Seika Machinery, Inc., a leading provider of advanced machinery, materials and engineering services, is pleased to announce its participation in SMTA International 2025, taking place October 21–23 at the Donald E. Stephens Convention Center in Rosemont, Illinois. Seika invites attendees to visit Booth 2718 to explore a dynamic lineup of process control, PCB cleaning, and measurement equipment designed to improve production efficiency, quality, and traceability.

Seika will highlight the following solutions on display:

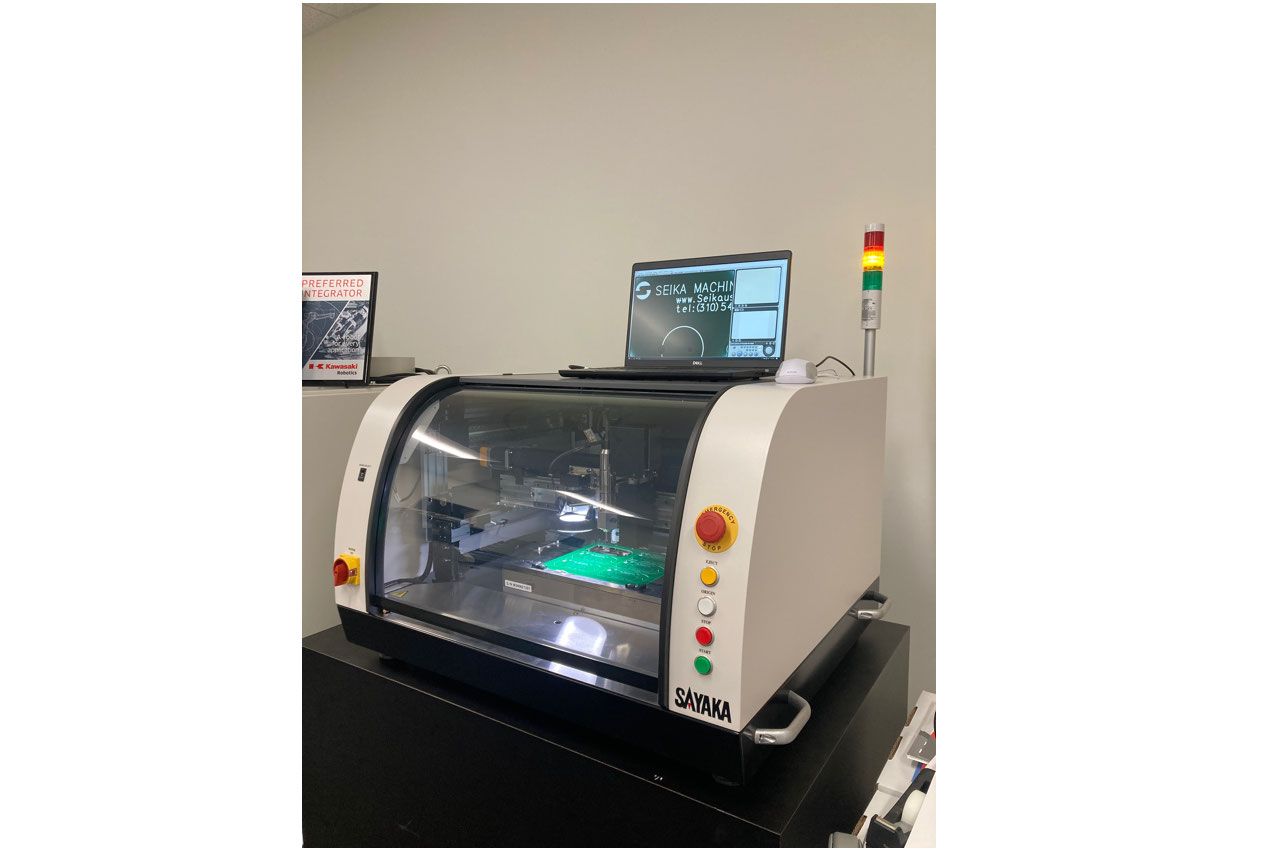

- Sayaka CT23S Router – A high-speed precision PCB depaneling system, ideal for stress-free separation of complex boards. The CT23S offers clean cuts with minimal mechanical stress, onboard easy programming and supporting a wide range of board materials and thicknesses.

- MB-302 Baking Cabinet – Designed to prevent moisture absorption in PCBs and low temperature baking of components, this dry cabinet ensures optimal storage conditions and long-term reliability in assembly processes.

- Malcom RCX Profiler – A reflow process analyzer that provides real-time thermal profiling for enhanced soldering process control, helping manufacturers optimize oven performance and solder joint quality.

- Malcom PCU-02V Viscometer – Accurately and quickly measures solder paste viscosity with fast and small samples of paste, allowing users to monitor print consistency and paste condition, which are critical for high-yield soldering processes.

- Malcom Dip Tester – Provides precise wetting and solderability testing for component leads and terminations, a valuable tool in high-reliability and lead-free manufacturing environments. Models for wave and selective soldering testing available.

- Unitech PCB Cleaner – An inline board cleaner that removes particulate and ionic contaminants prior to solder paste printing, improving adhesion and overall product performance.

- Kyowa Strain Gage Tester – Used for measuring mechanical strain and stress during PCB assembly processes including reflow, ICT, functional, and depaneling.

- Sawa Ecobrid Stencil Cleaner – A fully automatic and compact system that efficiently removes solder paste residues from stencils using a low-VOC solvent and ultrasonic cleaning action with a tact time of less than ten minutes.

“At SMTA International, we’re showcasing equipment that speaks directly to manufacturers’ needs—better process control, cleaner assemblies, and higher product reliability,” said Michelle Ogihara, Excutive VP, Seika Machinery. “Our solutions help customers build smarter, more efficient lines and maintain the quality standards their end markets demand.”

Seika Machinery continues to serve the North American electronics manufacturing industry with a robust lineup of production support, quality assurance, and sustainability-driven tools, trusted by leading OEMs and EMS providers in automotive, aerospace, medical, and industrial sectors.

To learn more and see the equipment in action, visit Seika Machinery in Booth 2718 during SMTA International 2025.

About Seika Machinery, Inc.

Seika Machinery, Inc. (SMI) is a subsidiary of Seika Corporation, Japan and member of the Mitsubishi Global Group. SMI provides electronics manufacturers with advanced machinery, superior materials and engineering services.