The APT-2400F and APT-2600FD are the latest high performance flying probe systems from TAKAYA. These high precision flying probe testers are specifically designed to meet the requirements of miniaturized electronics manufacturing and feature an impressive modular design. The systems are available in both stand-alone and in-line versions and offer maximum flexibility, precision and test range.

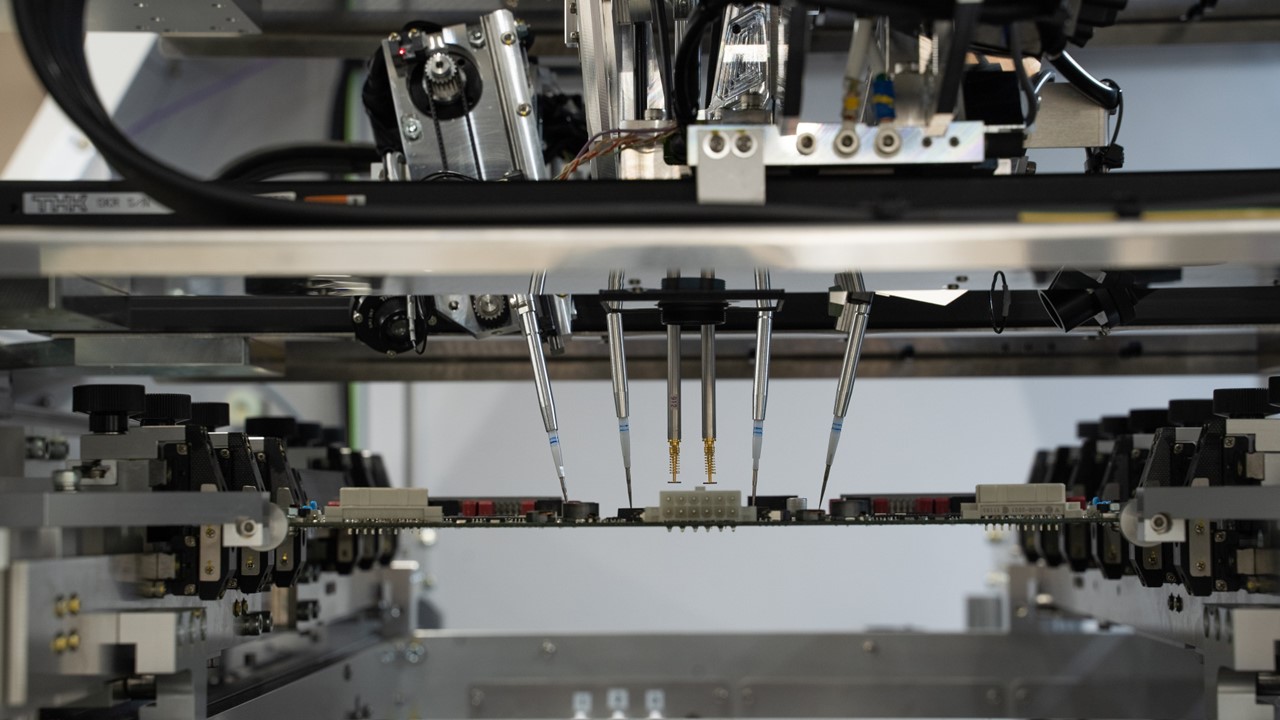

TAKAYA systems are based on a unique mechanical concept with six axes and ten flying probes, with four of them arranged vertically. This structure enables targeted access to hard-to-reach contact points, such as between tall components or on connectors, which significantly increases test coverage.

The APT-2400F is a single-sided test system with 4 axes and 6 flying probes, whereby 4 probes are angled, and 2 probes are vertical. With a minimum contact area of only 50 µm, even high density HDI printed circuit boards can be tested without any problems.

For more complex testing requirements, the systems, particularly the APT-2600FD two-sided tester, offer advanced functions. Two-sided testing saves time by eliminating the need to turn the board around, extends test coverage and increases test range. The multiprobe system allows simultaneous contact with multiple test points on the bottom side, thus supporting the integration of in-system programming (ISP). A laser measures the surface height of PCBs and components, facilitating the detection of defects such as protruding components, and the system automatically adjusts coordinates to PCB deformations to ensure test stability despite mechanical tolerances.

Soft touch control and modern vision solutions

The new systems are equipped with ‘Zero-Impact Probe Control’. This control reduces the speed of the test probes to zero immediately before contact, so that contact is only made via the spring pressure of the flying probes. This ensures particularly gentle and precise testing of even the most sensitive components.

The systems also feature state-of-the-art camera technology. The integrated CMOS camera system with liquid lens supports autofocus, 3D real map visualization and OCR. A separate remote camera monitors the testing processes in production and enables remote debugging. The test spectrum includes optical methods such as OCR, barcode and component recognition, and polarization testing. A special LED color sensor reliably analyses color tone, saturation and luminance.

Advanced electrical testing functions

Comprehensive electrical testing methods are available, including in-circuit tests, functional tests and open/short detection. Newly developed temperature sensors detect temperature- sensitive components and semiconductors to precisely identify defective or incorrectly assembled components. High resolution 16-bit measurement technology, 4-quadrant power supplies and a programmable AC generator ensure accurate results even for complex functional tests. In the SL version, the APT flying prober can process PCB formats up to 985 mm × 610 mm, making it suitable for a wide range of applications in development and manufacturing.

Industry 4.0 connectivity and economic advantages

The APT series is optimally tailored to modern manufacturing environments, allowing the powerful testing technology to reach its full potential. Standardized interfaces such as SMEMA, IPC-HERMES-9852 and OPC UA enable seamless integration into Industry 4.0 processes. An automatic cleaning system keeps the needles free of contamination and ensures stable test results. The user-friendly software allows for easy test program creation based on common CAD formats such as ODB++.

The series is designed for continuous operation and offers z-axis acceleration of up to 50G. It combines maximum mechanical precision with energy efficient performance. Thanks to their flexible design and high testing accuracy, the systems contribute significantly to reducing testing costs from prototype to mass production, while improving product quality and reliability.

With the APT-2400F and APT-2600FD series, SYSTECH Europe is positioning itself as a reliable technology partner for automated test solutions in European electronics manufacturing. Trade visitors can get detailed insights into both systems at productronica 2025 in Hall A1, booth 239.

About SYSTECH Europe

SYSTECH Europe offers comprehensive solutions in the field of test and production systems for the electronics and microelectronics industry. The company has been active on the European market since 1989, supporting its customers with state-of-the-art technologies and flexible systems. With a strong partner network in Europe and over 48 qualified engineers and technicians in 23 countries, the experts guarantee reliable support, particularly in the field of TAKAYA flying probe systems. The focus is on competent advice, high quality products and first-class service for more efficient manufacturing processes and sustainably increased quality.

Further information at: www.systech-europe.de/en/