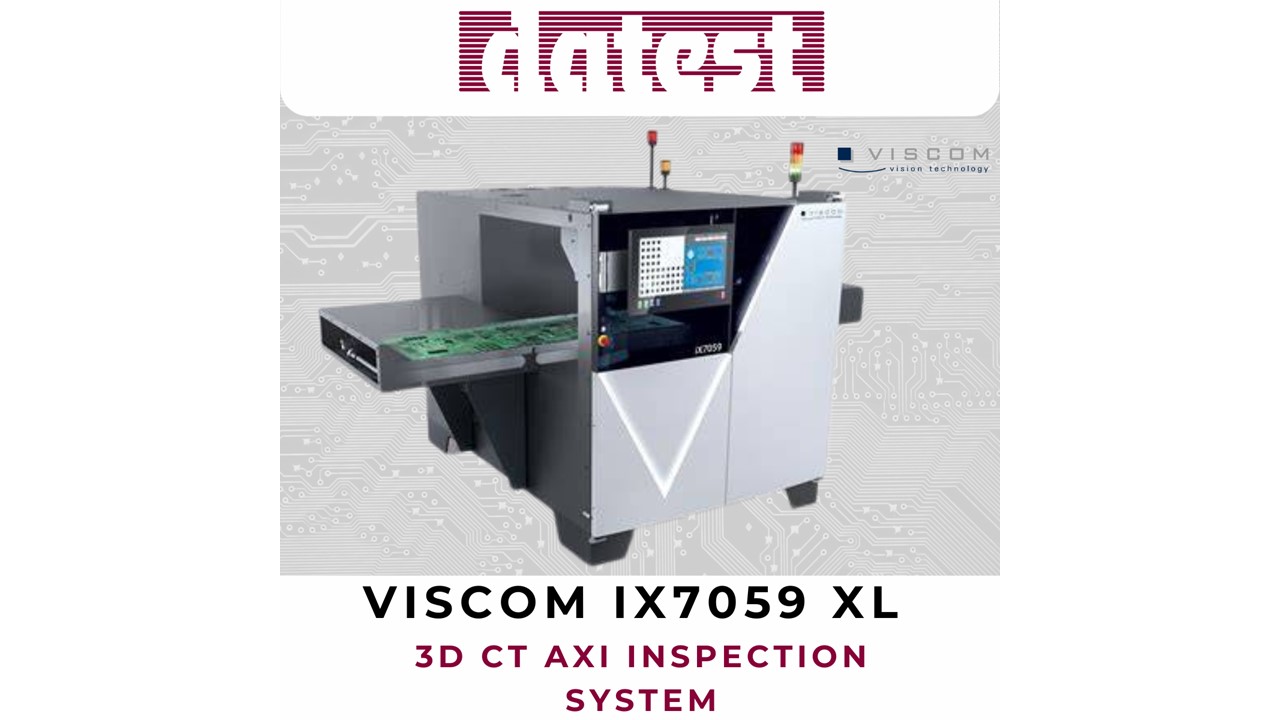

Datest, a trusted leader in advanced testing, engineering, inspection, and failure analysis services, and the go-to destination for when your boards misbehave and your AXI line goes on vacation, is thrilled to announce the arrival of its newest diagnostic weapon: the Viscom iX7059 XL 3D CT AXI Inspection System.

Yes, that’s a mouthful. But it’s also a game-changer.

With this addition, Datest levels up its non-destructive inspection capabilities, offering customers even faster, deeper, and sharper insight into what went wrong, where, and why, without needing to rip apart the hardware (or your hair).

“Sometimes you need answers yesterday,” said Robert Boguski, President of Datest. “We can’t rewind time, but we can give you answers that fast. The iX7059 sees through your boards like an airport scanner on espresso.”

What’s inside this beast?

- 3D Computed Tomography (CT) for slice-by-slice failure analysis

- High-resolution digital radiography for crystal-clear imaging of solder joints, BGAs, QFNs, and internal vias

- Extra-large board support for those oversized, overachieving assemblies

- Lightning-fast throughput, because downtime costs money, and time is money

- Closed-loop defect review tools that pair nicely with Datest’s engineering expertise

Whether your own AXI system is down, confused, or just not cutting it, Datest supports on-demand, contract-based 3D AXI and CT services, no long-term commitment, just immediate, actionable results.

And because it’s Datest, you also get:

- Engineers who actually interpret the data

- Support that speaks fluent root cause

- Turnarounds quicker than your line went down in the first place

- Backup and validation for EMS companies whose own AXI systems lack the advanced capabilities of Datest’s AXI system. Sometimes second opinions matter: here we are.

For over 40 years, Datest has been solving electronics mysteries that others give up on. Got a problem? We’ll see right through it. Literally.

For more information or to schedule your inspection, visit www.datest.com.