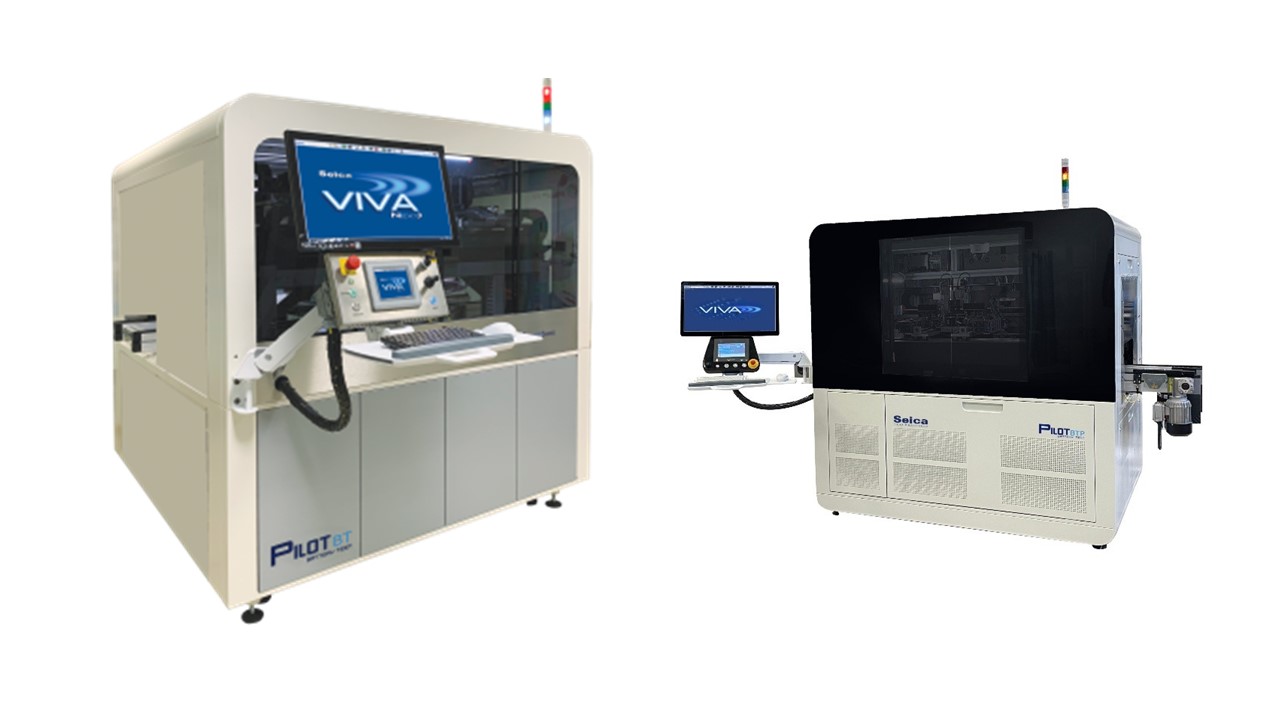

Seica, Inc. will showcase its latest advancements for EV battery testing in Booth 5025 at The Battery Show North America, taking place October 6–9, 2025 at Huntington Place in Detroit. Attendees will have the opportunity to explore Seica’s PILOT BT, a fully automated flying prober designed for high-volume EV battery pack testing, and learn more about the PILOT BTP, an advanced platform for prototype and low-volume battery testing.

With the rapid rise of electric vehicles, manufacturers face increasing challenges in validating complex and evolving lithium-ion battery configurations. Seica’s PILOT BT Series addresses these challenges with a validated, verified, and completely automated system for full-size EV battery packs. Featuring a large test area of 1050 x 865 mm and customizable conveyance options, the PILOT BT is engineered for speed, accuracy, and scalability. It is capable of performing precise, parallel Kelvin tests on more than 32 cells simultaneously, reaching nearly 4,800 cells per minute, ensuring efficient and repeatable results for high-volume production.

Equipped with up to four independent flying test heads, each with mini-fixtures for 4-wire Kelvin testing, the system delivers highly accurate bonding resistance measurements—critical to ensuring safety and reliability in EV battery modules. The integration of Seica’s VIVA> software and MES connectivity provides manufacturers with real-time production control, traceability, and security through multi-level user authentication.

For lower-volume applications, prototypes, or non-standard geometries, Seica offers the new PILOT BTP. This horizontal system features a 1050 x 865 mm test area, four flying heads, and speeds exceeding 600 tests per minute. Designed for flexibility and adaptability, the PILOT BTP enables full-size, parallel testing of EV packs where irregular layouts or new designs demand precision validation during NPI or pilot production.

Together, the PILOT BT, PILOT BTP, and the PILOT BTV (Seica’s vertical battery tester with three-sided access) form a complete family of solutions tailored to the diverse needs of EV battery manufacturing—from prototype to high-volume production. Visitors are also invited to stop by the booth to speak with Seica experts about the company’s advanced ACIR test solutions.

“The demand for safe, reliable, and high-performance EV batteries has never been higher,” said David Sigillo, Vice President, Seica Inc. “Our PILOT BT and PILOT BTP solutions provide manufacturers with the speed, flexibility, and accuracy needed to validate today’s most complex battery designs, while keeping pace with the innovations of tomorrow.”

Attendees of The Battery Show North America are invited to visit Seica at Booth 5025 to see these cutting-edge solutions in action and learn how the PILOT Series is helping global manufacturers accelerate innovation in EV battery production.

For more information about Seica, visit www.seica.com.