With ‘Smart Debug’, GÖPEL electronic takes AOI test program optimization to a new level: The new function of the PILOT AOI software uses real measurement data for intelligent tolerance adjustment. This addresses a well-known challenge: false rejects due to process fluctuations and tightly tolerated measurement functions – previously difficult to avoid due to a lack of statistical basis.

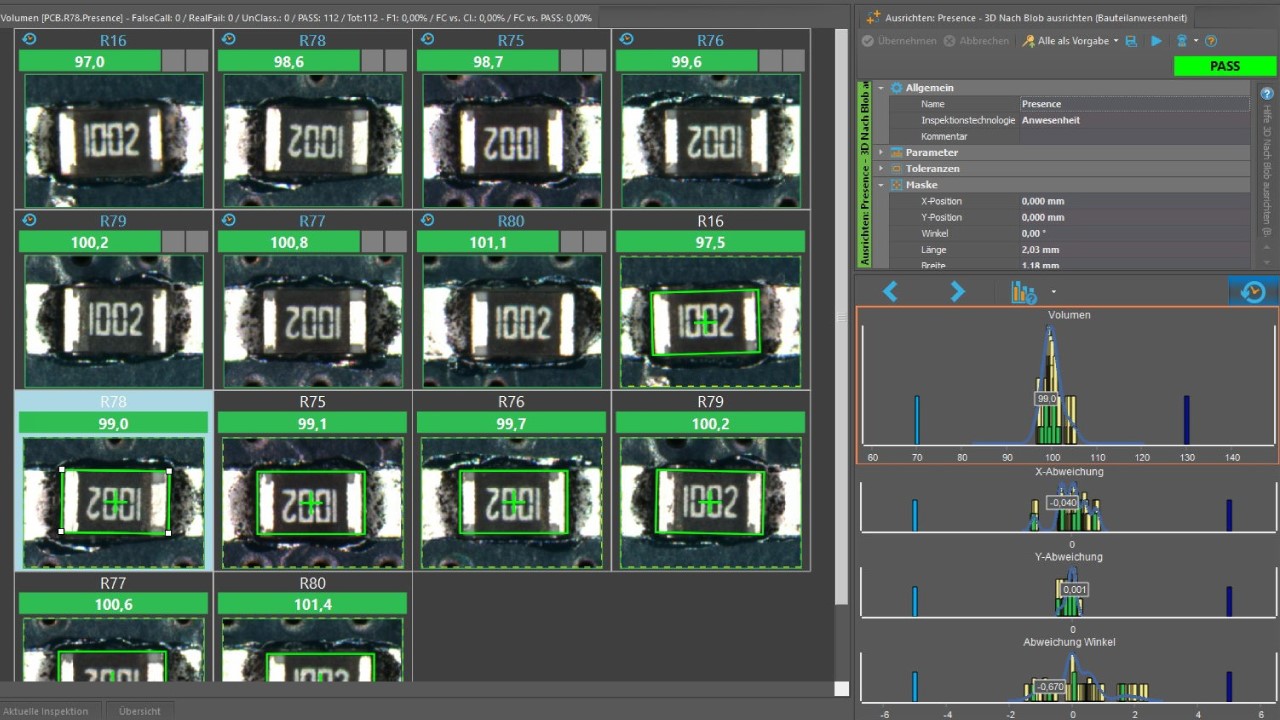

The new function accesses existing AOI measurement data and uses it as the basis for automatic tolerance adjustment. This allows test programs to be optimized in a targeted manner – without having to rely on estimated values. Results or measured values from other PCBA can also be used, which significantly increases flexibility and informative value. This significant development step in the optimization of inspection programs is made possible by a powerful database that stores all measured values from AOI inspections and the associated image data.

This information is available to the user at the touch of a button – clearly displayed, including failure images. This allows you to see directly how changed tolerance limits affect previous and latest test results: Are false rejects reduced? Is there a risk of defect slip? This saves time, increases security during program optimization, and enables targeted slip control. Additional support is provided by automatic tolerance adjustment based on statistical calculations – for even greater efficiency in debugging.

GÖPEL electronic already set standards in fully automatic AOI test program generation with “MagicClick.” “Smart Debug” is now the next technological step – this time in targeted optimization and data analysis.

“Smart Debug” is an integral part of the PILOT AOI software from the Jena-based manufacturer and will be delivered with new systems starting in September 2025. The function will be available to AOI users as an update starting in October 2025 with version 7.2.

More information: www.goepel.com/en/inspection-solutions/aoi.