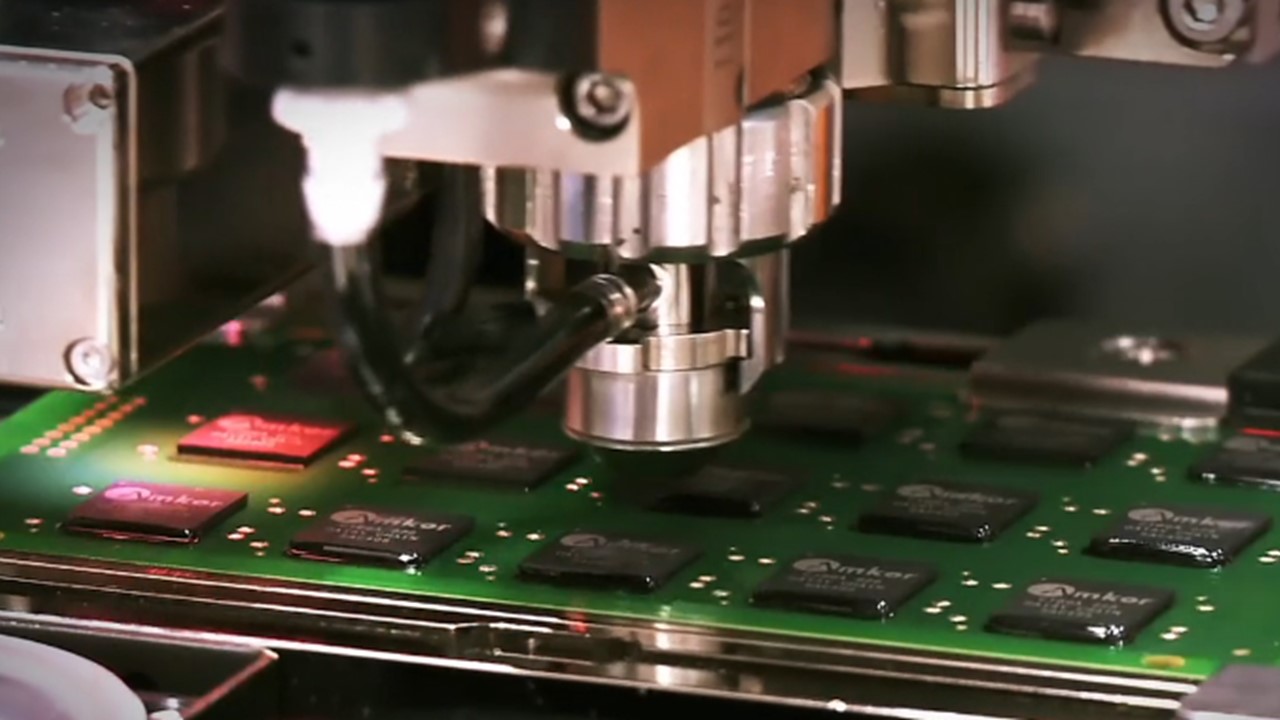

Libra Industries, a leading provider of systems integration and electronics manufacturing services (EMS), is excited to announce the addition of high-precision underfill to its in‑house manufacturing capabilities. This new service advances Libra’s ability to support advanced packaging needs such as flip-chip, BGA, CSP, PoP, and other high-reliability assemblies.

Underfill is typically a thermoset epoxy applied between semiconductor packages and PCBs or substrates. It delivers essential benefits: reinforcing solder-joint reliability, mitigating thermal expansion mismatches, improving thermal management, and enhancing mechanical durability.

The system supports multiple precision dispensing applications including underfill, cavity fill, die-attach, encapsulation, RTV/epoxy dispensing, and precision coating. Underfill-specific enhancements include:

- Jetting & capillary dispensing for accurate material placement and controlled flow

- Compatibility with high‑Tg, low‑CTE epoxy formulations, ideal for thermal cycling demanding assemblies

- Tight process control for void-free underfill and enhanced reliability

As devices grow smaller with higher I/O counts, underfill becomes essential for long-term performance. In-house precision dispensing ensures Libra’s customers benefit from:

- Improved structural integrity and solder-joint protection

- Enhanced thermal and mechanical performance

- Reduced reliance on outsourced processes, saving time, cost, and risk

- Reliable, consistent results tailored for advanced packaging formats like CSP and PoP

“With underfill now fully integrated into our workflow, we’re positioned to serve sophisticated PCBAs with the quality and efficiency engineers demand,” said Andrew Williams, CEO of Libra Industries. “This is a key advantage for customers in defense, medical, telecom, and industrial markets.”

For more information about Libra Industries and its industry-leading manufacturing services, visit www.libraindustries.com.