TapRen, a fast-growing electronics product development partner, is proud to introduce its rapid 30-day product manufacturing and delivery model — an end-to-end process designed to take customers from purchase order to functional hardware in 30 days or less.

For innovators, startups, and OEMs seeking to expedite their go-to-market timelines, TapRen provides a proven four-step approach that delivers quality, speed, and complete transparency. This streamlined workflow is now available for customers across industries, including IoT, wearables, embedded systems, and custom electronics.

How It Works:

TapRen’s 30-day process includes:

- Requirement & Feasibility Review

- Prototyping & Sample Testing

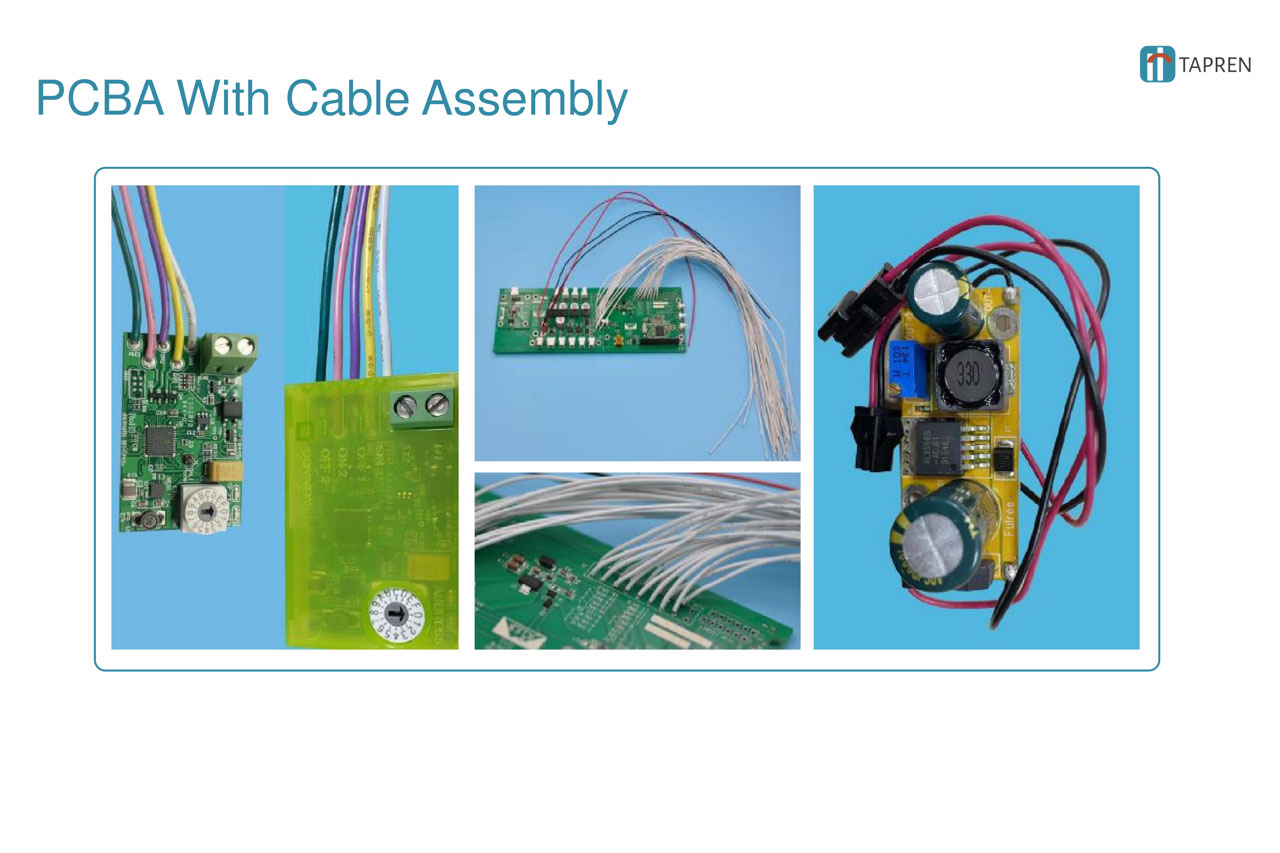

- Manufacturing & Assembly

- Final Delivery & Support

From initial DFM, DFT, and DFA to fully assembled and tested hardware, TapRen ensures full alignment with customer goals, providing frequent updates, responsive communication, and engineering expertise at every stage.

“Many of our clients come to us frustrated with long lead times and lack of visibility, especially during mass manufacturing,” said Tejas Tapsale, TapRen Tech Solutions Co-Founder. “We created this 30-day model to change that. It’s not just about speed, it’s about delivering quality products with confidence and clarity.”

TapRen’s full development process and case studies are now available to explore at www.tapren.com/how-we-work.

About TapRen

TapRen is an electronics development and manufacturing partner that helps customers bring ideas to life fast. From concept and prototyping to production and testing, TapRen combines agility with engineering precision to serve startups and established companies alike.