Poly Electronics LLC is excited to announce a transformative, seven-figure investment in its manufacturing capabilities with the addition of a second, state-of-the-art Surface Mount Technology (SMT) assembly line. Scheduled to be fully operational by August 1, 2025, this expansion will dramatically increase production speed, flexibility, and quality—delivering significant benefits to Poly Electronics’ customers.

The new SMT line will feature two Yamaha YSM pick-and-place machines, each capable of placing up to 90,000 components per hour (CPH), for a combined maximum throughput of 180,000 CPH. This upgrade more than doubles Poly Electronics’ manufacturing capacity, ensuring faster turnaround and even greater precision for clients.

Customer Benefits

With this investment, Poly Electronics’ customers will enjoy:

Shorter Lead Times:

Lead times will be reduced from the current 12 weeks to as little as 4 weeks by Q4 2025, allowing customers to respond more quickly to market demands and reduce their inventory costs.

Enhanced Product Quality:

Advanced inspection and quality control systems—including AI-powered 3D inspection and X-ray/CT scan technologies—ensure every product meets the highest standards of reliability and performance.

Greater Flexibility and Capacity:

The new SMT line increases production capacity and supports a wider range of product types and volumes, giving customers more options and scalability for their projects.

Improved Traceability and Consistency:

State-of-the-art automation and data-driven processes provide complete traceability and consistent, repeatable results, reducing the risk of defects and ensuring peace of mind.

Advanced Equipment Highlights

The new line integrates a suite of best-in-class equipment, each selected for its cutting-edge features:

-

ASYS Screen Printer

Learn more-

High-precision printing with automatic alignment for consistent solder paste deposition

-

Fast changeover and intuitive touchscreen controls for maximum uptime

-

-

Koh Young KY8030-2 AI-Powered SPI (Solder Paste Inspection)

Learn more-

Real-time 3D solder paste inspection with AI-driven defect detection

-

High-speed, high-accuracy analysis to ensure optimal solder quality

-

-

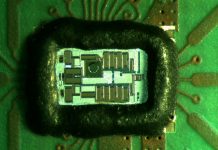

Koh Young Zenith AOI (Automated Optical Inspection)

Learn more-

True 3D inspection for comprehensive defect coverage

-

Advanced algorithms for reliable detection of even the smallest component defects

-

-

Tech Valley Arirang 130CT X-Ray & 3D CT Scan System

Learn more-

High-resolution X-ray and 3D CT imaging for thorough post-process inspection

-

Ideal for verifying BGA and hidden solder joints, ensuring product reliability

-

-

Maker Ray Through-Hole AOI

Learn more-

Automated inspection of through-hole components for complete assembly verification

-

Fast, accurate detection of soldering and placement defects

-

-

PDR IR-E3 BGA Rework System

Learn more-

Precision infrared heating for safe, effective BGA rework and repair

-

Advanced thermal profiling for repeatable, high-quality results

-

This investment leverages artificial intelligence, 3D inspection, and advanced automation, providing best-in-class component placement accuracy, quality control, and production traceability.

About Poly Electronics

Based in Elkhart, Indiana, Poly Electronics LLC is a global provider of custom electronic manufacturing services, offering engineering, sourcing, assembly, testing, and distribution. The company serves a wide range of industries, including agriculture, industrial, commercial equipment, automotive, and recreational vehicles. ISO 9001:2015 certified, Poly Electronics is known for high-quality, zero-defect products and reliable on-time delivery. With over 3,500 custom electrical products engineered, the company maintains strong, long-term client partnerships.