SHENMAO America, Inc. has released two new high-performance solder pastes — SH-0595-210 and SH-05X25-210 — developed specifically to meet the demanding requirements of high-power component assembly. Engineered with cutting-edge flux chemistry and exceptional process stability, these pastes provide manufacturers with reliable solutions for applications such as die attachment and IGBT module production.

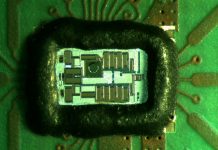

With alloy compositions of Sn95Pb5 (SH-0595) and Sn92.5Pb5Ag2.5 (SH-05X25), SHENMAO offers flexibility for manufacturers to choose the ideal formulation based on their specific power electronics needs. Both solder pastes feature excellent wetting properties on copper lead frames and die surfaces, even under challenging or narrow reflow process windows. The result is consistently high-quality solder joints with minimal defects.

SH-0595-210 and SH-05X25-210 are halogen-free (ROL0) and manufactured with no intentionally added halogens, meeting RoHS, RoHS 2.0, and REACH compliance standards. Extensive in-house testing has confirmed that the pastes produce no solder splash, even in critical thermal environments, and leave behind minimal, non-charred flux residue that is easy to clean.

Due to SHENMAO’s innovative flux design, both products also demonstrate excellent voiding performance, helping ensure reliable long-term performance in thermally demanding applications. Additionally, users can expect smooth printability and strong solderability across a variety of substrate finishes.

These solder pastes are optimized for use in high-reliability electronics, especially where thermal and mechanical stress are high, such as in power semiconductors, automotive systems, and industrial energy conversion products.

To learn more about SHENMAO’s high-performance solder materials, visit www.SHENMAO.com.