BEST Inc., a leader in electronic component rework services, training, and products is pleased to introduce StikNPeel™ rework stencils. This innovative product is designed for printing solder paste for placement of gull wing devices such as quad flat packs (QFPs) or bottom terminated components.

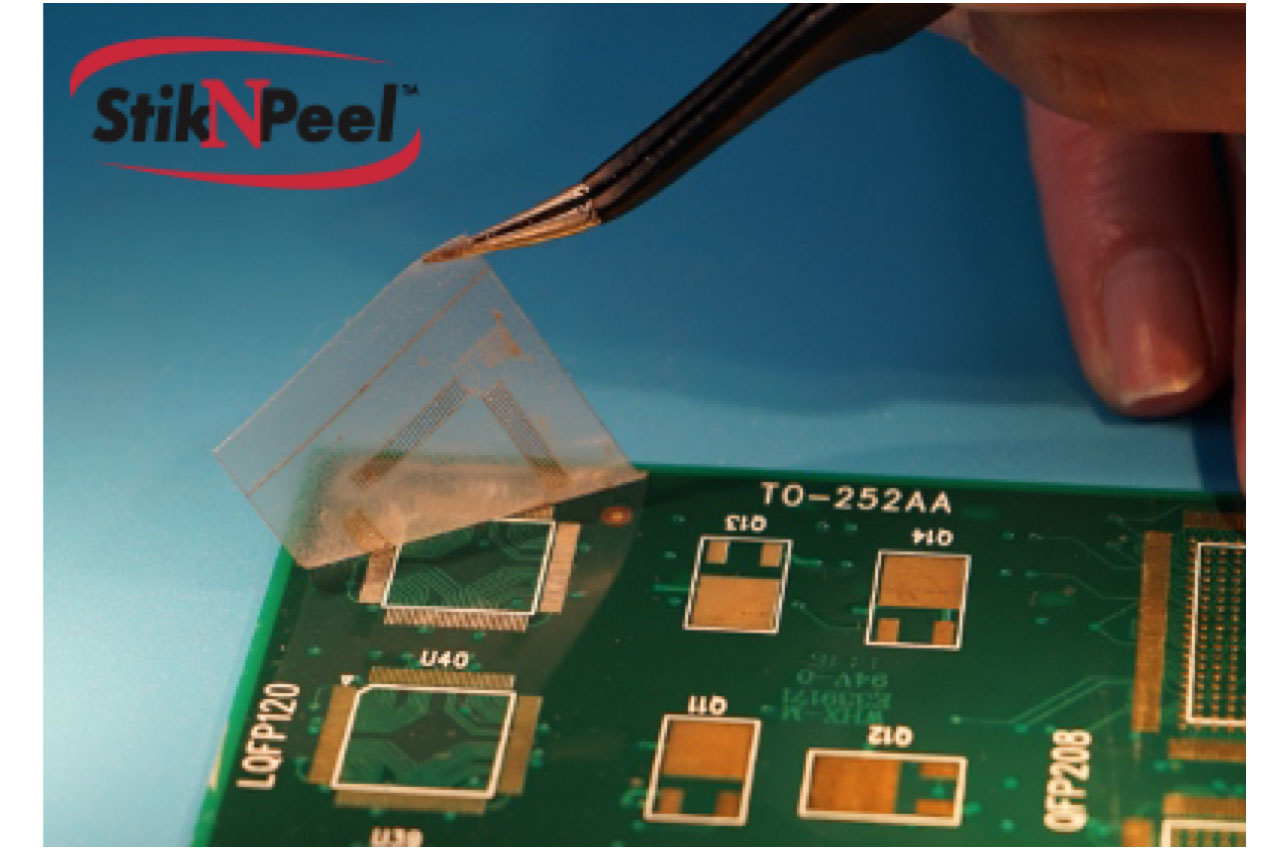

StikNPeel™ simplifies the process of selectively printing solder paste onto a printed circuit board. The process is as simple as peeling off the stencil backing, aligning in the proper location, and placing the stencil on the circuit board pad site. The StikNPeel™ stencil is secured in place on the PCB via a repositionable adhesive backing. Once properly placed, solder paste is dispensed across the stencil to obtain sufficient solder paste deposition. Next, the StikNPeel™ stencil is peeled off the circuit board leaving uniform solder paste volume in the aperture areas without any remaining residues or visible signs of rework. Once the stencil is removed, you’re ready for component placement.

Using StikNPeel™ stencils streamlines component placement without the common issues and mess that come with using metal stencils. The flexible material and adhesive backing ensure the board and stencil remain coplanar, preventing solder paste smearing and improving first-pass yields. Once aligned and pressed into place, the stencil remains adhered to the board providing uniform solder paste distribution. Utilizing this process eliminates the need for time-consuming masking around the rework area. Additionally, the StikNPeel™ stencil can be equipped with peripheral flaps to allow tighter positioning when navigating neighboring devices. Compared to our stay-in-place stencils, StikNPeel™ is removed from the board prior to component placement and leaves no visible evidence of rework.

StikNPeel™ rework stencils are custom made to your exact device requirements without the need for expensive tooling. One pack consists of 10 stencils in a pink anti-static bag. No minimum order requirements apply. Typical lead time is 3-5 days for up to 4 packs after check plot approval. Approved files include Gerber, DXF, or component mechanical specs.

About BEST Inc.

BEST Inc. is an ISO 9001:2015 and ITAR certified provider of PCB and component rework services and products along with being a certified IPC Training Center. Our commitment is to provide the highest quality services and products with outstanding customer service to serve our customers’ needs.

For more information on BEST products, please contact Chris Edwards at 224-387-4302 or Products@solder.net.

For more information on BEST services, please contact Laura Ripoli at 224-387-3255 or Service@solder.net.