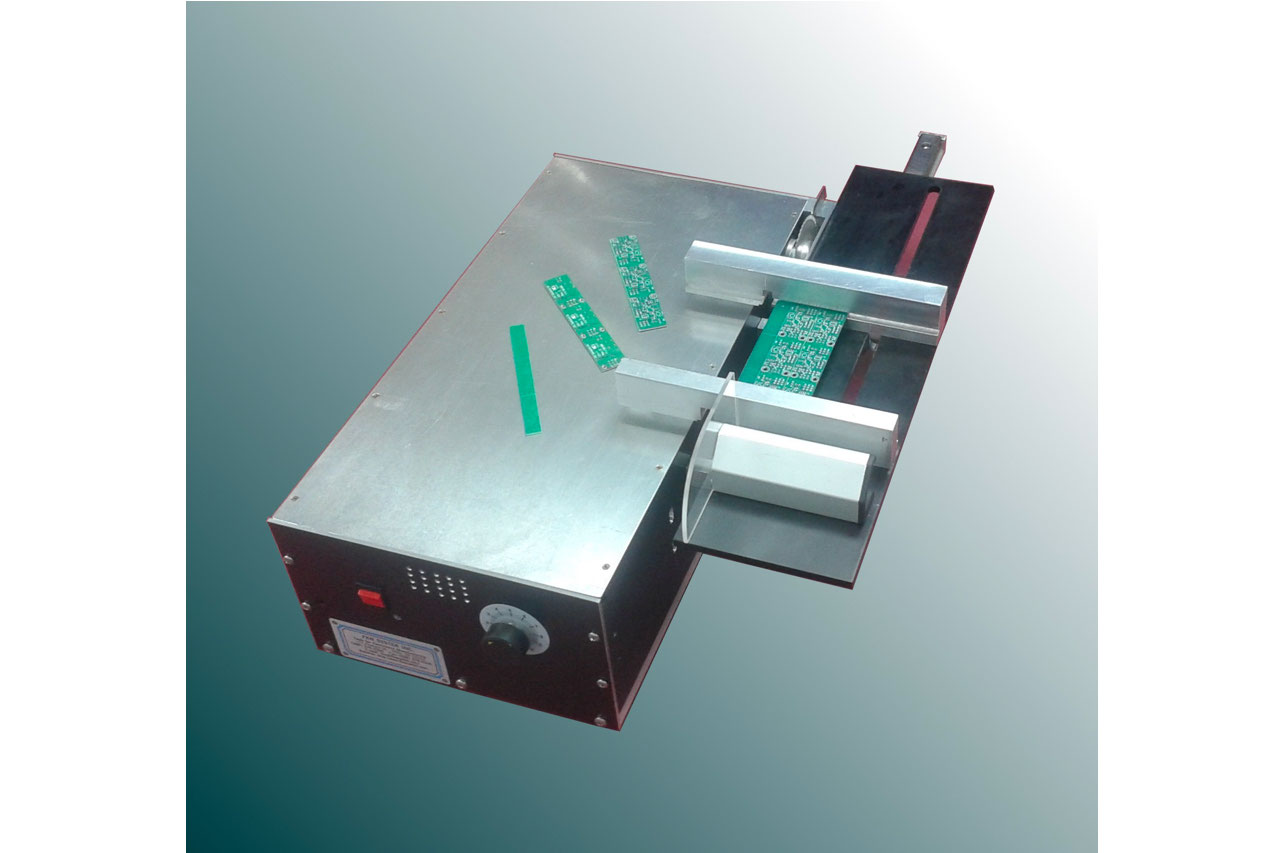

Now available from FKN Systek, a table top cut off saw to use in singulating PCB panels up to 12” long. The S100 saw provides a low stress method to singulate panels and backplanes with sensitive surface mount components close to the edge of the parting section. The operator places the PCB to be singulated onto the positioning rails of a linear bearing guided table, and moves the table with the panel forward to make a smooth clean cut. Adjustable guide blades underneath the scoreline make board alignement quick and easy.

The cutting depth can be set to just cut through the PCB itself. Any components which overhang the parting line will remain intact. A built in dust extraction plenum around the saw blade pulls particles out of the environment into a HEPA filter. An additional clean up vacuum wand can be switched on as desired to remove any dust build up on the pcb edges. A dust extraction vacuum is available separately.

The long lasting diamond saw blade is 2.95″ (75mm) in diameter and .022″ thick. Custom tooling for difficult to place panels can be provided on request. Boards up to 0.25” (6.35 mm) thick can be cut on the S100.