Robotas Technologies Ltd., pioneers in manual Through-Hole Technology (THT) component placement and clinching systems, offers a practical and up to date solution for manufacturers struggling with outdated Automated Axial, Radial, and DIP insertion machines. As these machines become costly to maintain and difficult to repair due to limited spare parts, many companies face challenges in sustaining their THT production. Robotas’ Mascot Systems provide a streamlined, affordable alternative that maintains high-quality results without excessive investment.

Older insertion machines require substantial upkeep, making them impractical for companies that produce small or varied PCB assembly runs. Frequent breakdowns, limited availability of replacement parts, and lengthy setup times further reduce their efficiency. As a result, many manufacturers are left searching for a cost-effective way to continue their THT production without committing to expensive new equipment.

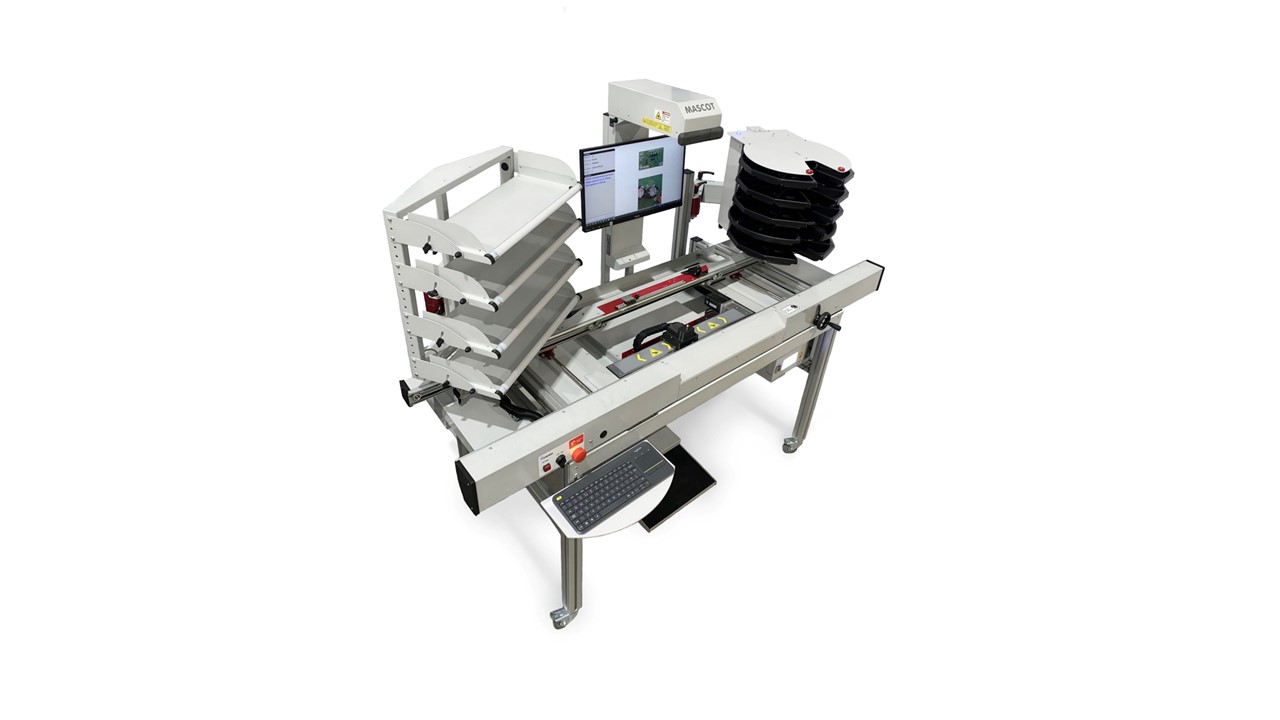

Robotas’ Mascot Systems optimize THT assembly with advanced features that ensure precision and efficiency. The Mascot Clinch Conveyor utilizes proprietary Clinch Technology, allowing component leads to be clinched in any direction (360°) and at adjustable bend angles from 35° to 85°, securing components in place before wave soldering.

In addition, the Mascot’s laser pointer guides operators through the assembly process, whist its Carousels and Dynamic Pick-to-Light Arrays automate component delivery, eliminating the need to search for parts. This intuitive workflow increases speed, reduces errors, and enhances productivity.

Unlike traditional insertion machines that demand high setup costs and are only viable for large-scale production; however, Mascots provide the same level of accuracy and reliability at a fraction of the cost. Quick to install and easy to configure, these systems offer flexibility for low-to-mid volume production while maintaining consistent quality. Integrated Mascot Software also assists with polarized component placement, indicating correct component orientation every time.

To further enhance accuracy, Robotas offers the Mascot Verify Module, which can be added to any Mascot System. Using camera inspection technology, this module verifies component presence, absence, and polarity before soldering, significantly reducing human error and minimizing the need for rework.

For manufacturers seeking a reliable, cost-effective alternative to aging insertion machines, Robotas’ Mascot Systems offer the perfect balance of affordability, efficiency, and precision. By streamlining the THT process, reducing errors, and delivering high-quality results, Mascot Systems provide a future-ready solution for modern electronics assembly.

Robotas’ Mascot Systems are also available for online demonstrations, or on-site visits. To experience Robotas’ THT Technology, please contact sales@robotas.com. To learn more about Robotas Technologies and its industry-leading assembly systems, visit www.robotas.com.