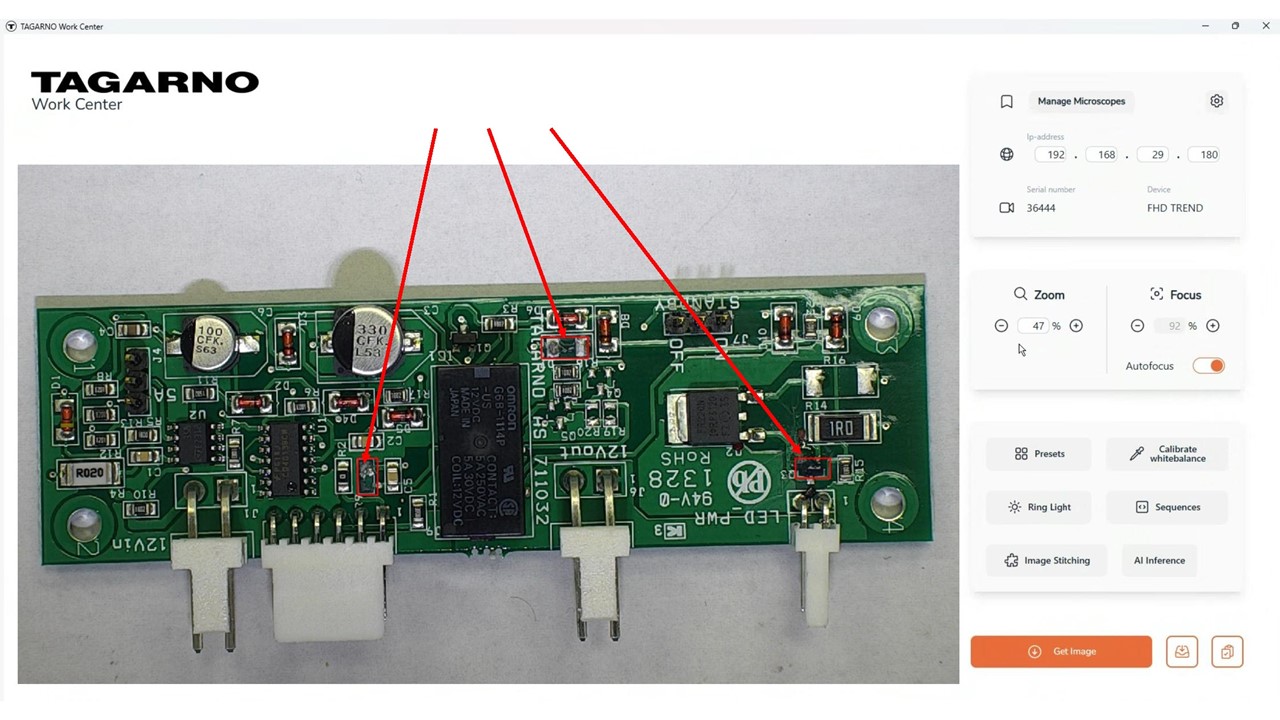

TAGARNO, a renowned Danish manufacturer of high-quality digital microscopes, has unveiled its latest AI-powered platform designed to enhance inspection processes in the electronics industry. The new platform, showcased at the 2025 IPC APEX, integrates artificial intelligence to automate defect detection, improve accuracy, and streamline quality control workflows.

In a recent interview with What’s New in Electronics, TAGARNO’s Jake revealed how the company is harnessing AI to tackle common challenges in electronics manufacturing. The AI-driven system leverages advanced vision-based algorithms to detect anomalies, such as missing components, and allows operators to Accept or Reject AI-generated suggestions. With each interaction, the system continuously learns and refines its accuracy, making inspections more reliable and efficient over time.

Traditional microscopy inspection relies heavily on manual oversight, which can be time-consuming and prone to human error. TAGARNO’s AI-powered platform introduces an innovative approach, enabling real-time, intelligent decision-making that optimizes production efficiency and ensures consistent quality control.

“We’re offering electronics manufacturers an AI-based solution that not only identifies issues more accurately but also evolves through continuous learning,” said Jake. “By integrating AI with digital microscopy, we are setting a new standard for precision and efficiency in quality assurance.”

TAGARNO is actively seeking companies facing routine inspection challenges that could benefit from vision-based AI solutions. Whether manufacturers are looking to optimize defect detection or develop their own AI-powered workflows, TAGARNO’s platform provides the foundation for smarter, more adaptive quality control processes.

To see the full What’s New in Electronics interview: Watch Here.

For more information about TAGARNO’s AI-powered platform, visit www.tagarno.com or contact their U.S. office directly.