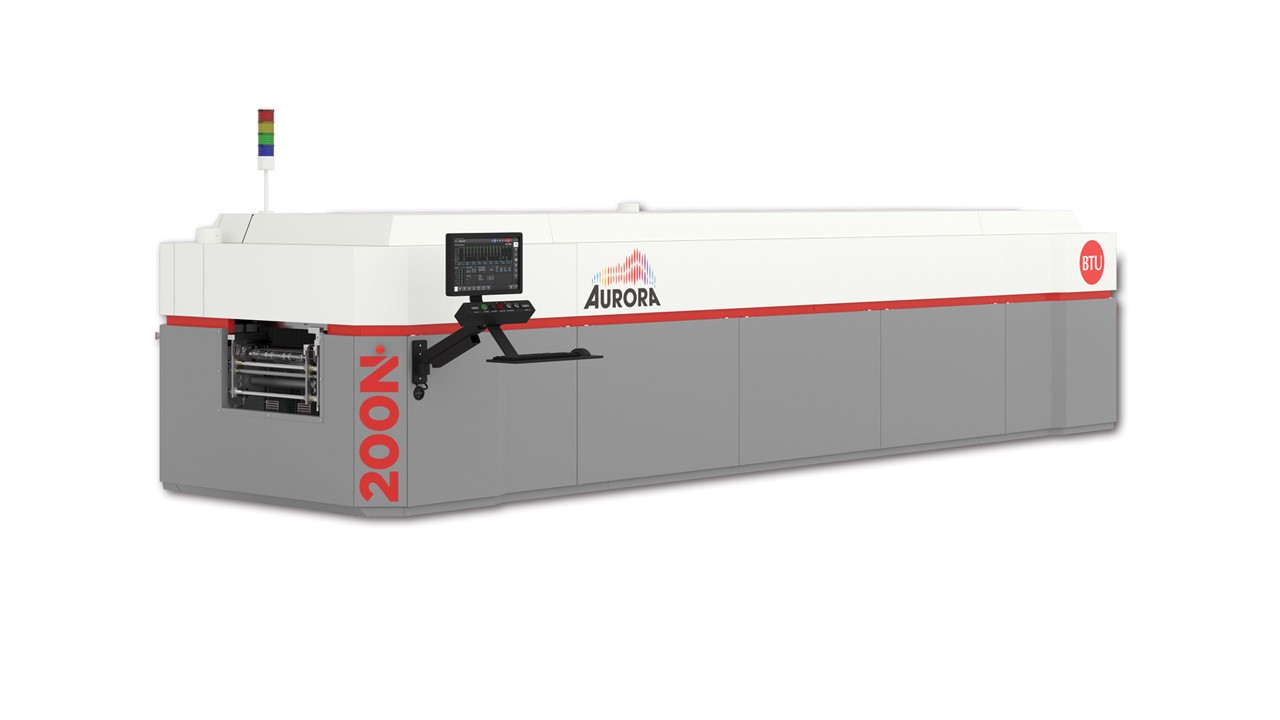

BTU International, Inc., a leading supplier of advanced thermal processing equipment for the electronics manufacturing market, is proud to announce that it has been honored with a 2025 NPI Award in the Soldering – Reflow category for its Aurora 200N reflow oven. The Aurora 200N redefines reflow oven technology with its groundbreaking design and advanced features.

As the longest reflow oven ever produced by BTU, it boasts an unprecedented 200 inches of heated length, setting a new industry standard for high-speed, high-performance manufacturing. Designed to meet the needs of modern production environments, the Aurora 200N offers factory-configurable heating and cooling zones, a first in the industry. This unique capability allows manufacturers to optimize thermal performance for heavy boards, controlled cooling rates, and increased throughput demands.

Beyond its thermal performance advancements, the Aurora 200N introduces a modular design that solves logistical challenges for global manufacturers. The system is shipped in two manageable pieces, streamlining installation and transportation—a significant advantage for factories with space or handling constraints.

“The Aurora 200N is more than just the longest reflow oven we’ve ever built—it’s a major step forward in precision, flexibility, and efficiency,” said Rob DiMatteo, Vice President & General Manager of BTU International. “With configurable heating and cooling zones, a modular design for seamless deployment, and advanced process control features, this system empowers manufacturers to push the boundaries of high-performance soldering like never before.”

The Aurora 200N also leverages BTU’s industry-leading WinCon 8 operating system, featuring:

- Smart Power energy reduction for enhanced sustainability

- Aqua Scrub flux management to improve process reliability

- Industry 4.0-ready connectivity for seamless factory integration

- Bar code-enabled traceability and Profile Guardian for advanced process control

With the Aurora 200N, manufacturers can upgrade their thermal processing capabilities while maintaining operational continuity and efficiency.

To learn more about BTU, visit www.btu.com.