Bold Laser Automation is proud to announce the launch of its latest innovation, the PS1016A Mechanical Probe Station, a system designed to improve precision testing in advanced manufacturing. Built to deliver accuracy and efficiency, the PS1016A integrates 16 mechanical probes with the capacity to scale up to 64 probes and higher, offering flexibility for manufacturers in electronics, PCBs, medical devices, automotive, and aerospace.

Key features include an adjustable vertical stroke (4–12 inches) for flexibility, seamless data handling via Gigabit Ethernet, and an operator-friendly control interface. With safety at its core, the system incorporates advanced features such as light curtains, emergency stops (EMO), and OSHA-compliant enclosures, ensuring safe operation in production environments.

“The PS1016A Probe Station exemplifies a commitment to creating solutions that adapt seamlessly to our customers’ unique workflows,” said Todd E. Lizotte, co-founder and CEO of Bold Laser Automation.

The probe station delivers the following benefits:

- Enhanced Scalability: Start with 16 probes and easily expand to 64 probes and higher for evolving production needs.

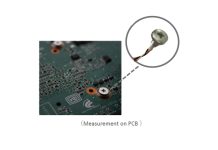

- Unmatched Precision: High-performance Keyence GT2 Series probes ensure consistent and accurate measurements across diverse applications. The PS1016A is particularly valuable in environments that require non-destructive testing (NDT), where product integrity must be maintained while performing in-depth inspections.

- Increased Efficiency: Modular design and intuitive controls streamline testing processes, reducing downtime and optimizing throughput.

- Versatility Across Industries: Ideal for testing foils, films, and glass for biomedical devices, sensors, robotic components, planar electrodes, and more.

- Safety and Reliability: Designed for compliance with strict manufacturing and workplace safety standards.

Whether for prototyping or full-scale production, the PS1016A sets a new standard for precision testing, helping manufacturers achieve greater productivity, quality, and confidence in their products.

“Precision and safety are non-negotiables in advanced manufacturing, but we also know that cost efficiency is crucial for our customers,” added Lizotte. “This system helps manufacturers improve throughput, reduce waste, and maximize their return on investment—all at a highly competitive price point.”

About Bold Laser Automation

Bold Laser Automation specializes in developing advanced laser systems for industrial applications, focusing on innovation, reliability, and customer satisfaction. For over 30 years, the founders have worked within the field of applied laser processing technology covering processes for drilling, thin film removal, micromachining, micro welding, cutting and marking, measurement, and inspection. Committed to excellence, Bold Laser Automation delivers advanced solutions tailored to the evolving needs of its clients worldwide.

For more information or to schedule a demonstration, contact Bold Laser Automation at (603) 413-5601, sales@boldlaserautomation.com, or visit www.boldlaserautomation.com.

To access the latest book from Todd E. Lizotte, CEO and co-founder of Bold Laser Automation, see Laser Beam Shaping Applications, Second Edition.