Mycronic, the leading Sweden-based electronics assembly solutions provider, is introducing two new machine models MYPro A40SX and A40LX to its next-generation MYPro A40 pick-and-place platform, equipped with the all-new MX7 high-speed mounthead technology.

Two new versatile, high-flexibility models

The new MYPro A40SX and A40LX pick-and-place models combine unrivalled flexibility with high-accuracy placement, industry’s fastest changeovers and a benchmark for manufacturers with a highly variable mix of products and frequent new product introductions (NPI). Thanks to a new high-speed MX7 mounthead technology, placing components six times larger than previous high-speed mountheads greatly improves the MYPro A40 productivity and placement speed.

Key features

- Top speed of 29,000 CPH (SX) / 18,000 CPH (LX)

- Up to 224 feeder positions

- Full range of components in one machine

- On-the-fly changeovers

- Handle short tapes and non-standard carriers

- Electrical verification of resistors, capacitors, diodes and transistors

- Full traceability

The two new models complement the MYPro A40DX, released in 2023, offering a top placement speed of 59,000 CPH and a feeder capacity, up to 224 feeder positions. The MYPro A40 series is compatible with Mycronic’s unique modular component feeding system Agilis™, designed for accuracy, ease of use and convenience. It sets the standard for intelligent feeders and magazines for tapes, sticks and trays.

Turning up the volume

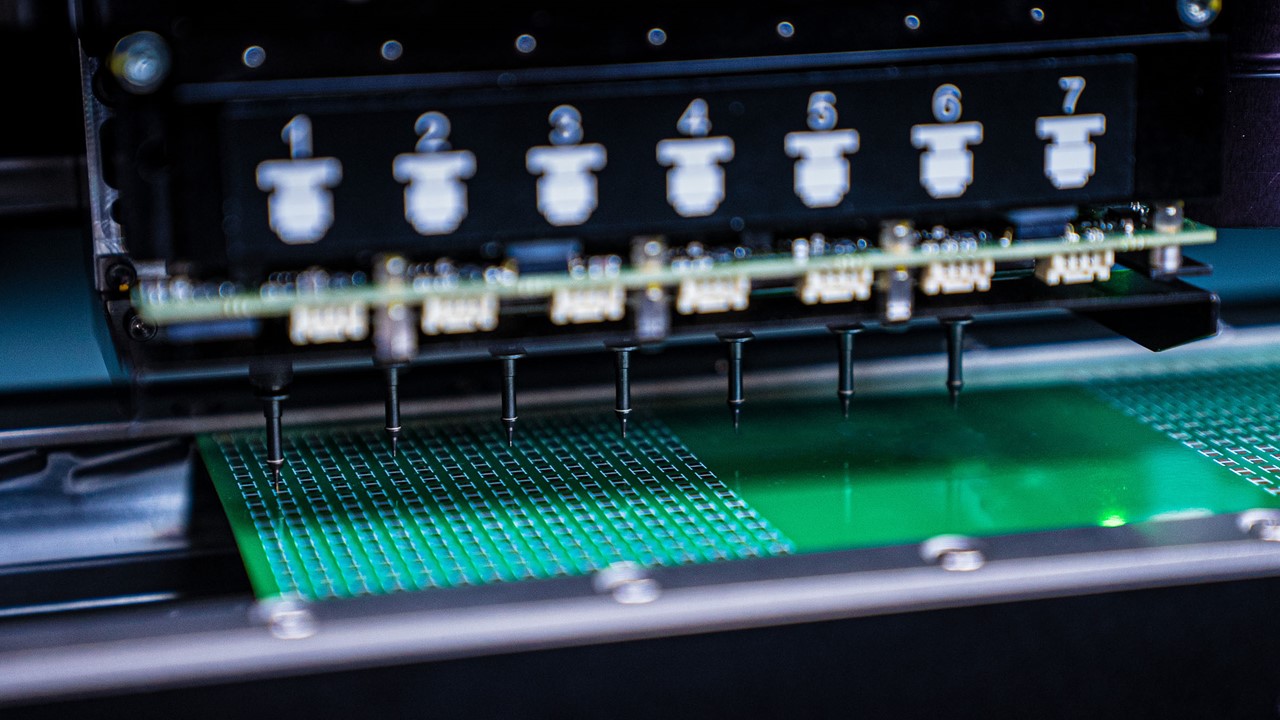

The new MX7 mounthead achieves higher placement speeds by integrating seven independent placement nozzles steered by fourteen individual Z and theta motors. Thanks to an advanced, proprietary motion control system, updating at a rate of 80,000 times per second, it ensures an unprecedented combination of control and speed by optimizing every movement across up to 224 interchangeable feeder positions and 640×510 mm board placement area.

Expanded component range

To accommodate a wider range of applications and technologies, the MX7 mounthead technology expands the upper component size limit by six times, enabling placement of components as large as 45×45×15 mm or 150×40×15 mm. Its capabilities extend down to the placement of components as small as 0.4×0.2 mm (01005), allowing producers to manage the continued miniaturization of PCB technologies. A high precision mounthead complements the MX7 to mount chip components as small as 0.3×0.15 mm (009005), and components as large as 99×73×22 mm.

New graphical user interface

A newly designed graphical user interface has been introduced to simplify both training and pick-and-place operations for even novice operators. By providing straightforward touchscreen guidance, the MYPro A40 moves the pick-and-place process another step forward towards Mycronic’s ambition of fully automated one-click operations.

Continued leadership in flexible PCB assembly

The MYPro A40 continues in the footsteps of its predecessors by again pushing the boundaries of flexible PCB assembly. With the industry’s fastest changeovers, most flexible feeders and an array of powerful process control systems, the MYPro Line production concept is designed to keep manufacturers ahead of the accelerating innovation cycles, complex board designs and rapid prototyping demands that are increasingly driving the electronics industry. Complete with standard Hermes and CFX interfaces, it offers a versatile solution that can easily be integrated into virtually any intelligent factory environment.

“We are thrilled to announce the introduction of the two new machine models, MYPro A40SX and A40LX, now completing the MYPro A40 series” says Clemens Jargon, Sr VP High Flex Division. “These additions represent a significant leap forward in our product offering, enabling our customers to achieve even greater flexibility and precision in their production processes.”

For further details, product specifications or inquiries on the new portfolio of MYPro A40 pick-and-place solutions, contact your local Mycronic sales office or visit mycronic.com.