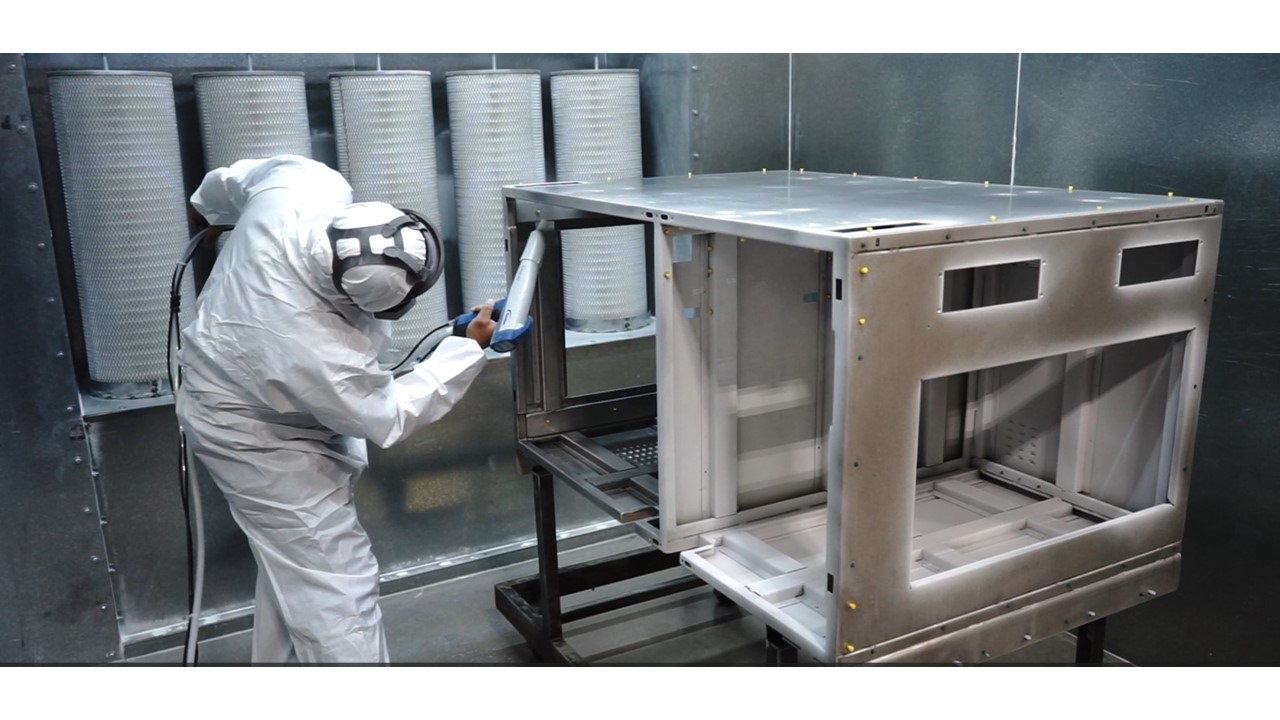

Libra Industries, a privately-held systems integration and electronics manufacturing services (EMS) provider, is excited to announce the expansion of its state-of-the-art Powder Coat paint line at its Guaymas, Mexico facility. This addition significantly enhances the company’s surface finishing capabilities, complementing its extensive manufacturing services.

Andrew Williams, CEO of Libra Industries, commented on the expansion: “We are thrilled to offer our clients this advanced powder coating solution in Guaymas. It provides greater flexibility for high-volume production, custom applications, and the ability to deliver top tier finishes with unbeatable efficiency. These upgrades are a key step in broadening our services while maintaining the high standards of quality our clients expect.”

Two Painting Lines, Full Capabilities

The facility now features two distinct powder coating lines:

• Batch Line: Designed for larger parts and smaller production runs, capable of handling parts up to 98″ wide, 78″ long, and 40″ high.

• Conveyor Line: Ideal for larger batch sizes, processing parts up to 33″ wide and 53″ high, with a variable speed of up to 6 ft per minute.

Comprehensive Pretreatment System

Both lines incorporate a six-stage pretreatment process that ensures the highest quality surface preparation:

1. Degreaser

2. Rinse (deionized water)

3. Rinse (deionized water)

4. Zirconium (Zr) coating

5. Rinse (deionized water)

6. Seal

These stages ensure that all components are thoroughly cleaned and prepped, improving the adhesion and longevity of the powder coating.

Testing to ASTM Standards

To guarantee the highest level of quality, Libra’s powder coating process follows stringent ASTM testing methods, including:

- Color Measurement: ASTM E 308

• Thickness Test: ASTM B244

• Bending Test: ASTM D-522 Method B

• Adhesion Test: ASTM D 3330, Method A

• Gloss Measurement: ASTM D 523

• Hardness Test: ASTM D 3363

• Curing Test: ASTM D5402-15

Eco-Friendly and Durable Solutions Libra Industries’ powder coating process offers an environmentally friendly alternative to traditional wet painting, utilizing high-temperature coatings for durable, aesthetically pleasing finishes. The system supports multi-coat applications, providing quick turnarounds for both small orders and large-scale production runs.

This expansion reinforces Libra Industries’ dedication to quality, innovation, and customer satisfaction, offering a comprehensive solution for clients in the Aerospace, Defense, Medical, and Industrial sectors.

For more information about Libra Industries and its full suite of contract manufacturing services, visit www.libraindustries.com.