Facing inefficiencies and quality control challenges during pre-production, Microboard turned to ScanCAD to improve circuit card assembly inspections. Traditional reliance on Gerber data from board shops resulted in delayed feedback, rework, and scrap—adding as much as 10% to pre-production costs. Manual inspections further slowed the process and left subtle defects undetected.

ScanCAD empowered Microboard to perform automated, in-house inspections, identifying issues such as board stretch, over-etching, and component misalignments before they disrupted production. The technology also created digital records for enhanced traceability and quality assurance, a critical feature for regulatory compliance.

Since implementing ScanCAD, Microboard has achieved a 40% reduction in pre-production cycle times, fewer line shutdowns, and a 20% reduction in overall costs. The Executive Director of Technology calls the tool indispensable, particularly for projects involving smaller components and high-complexity assemblies.

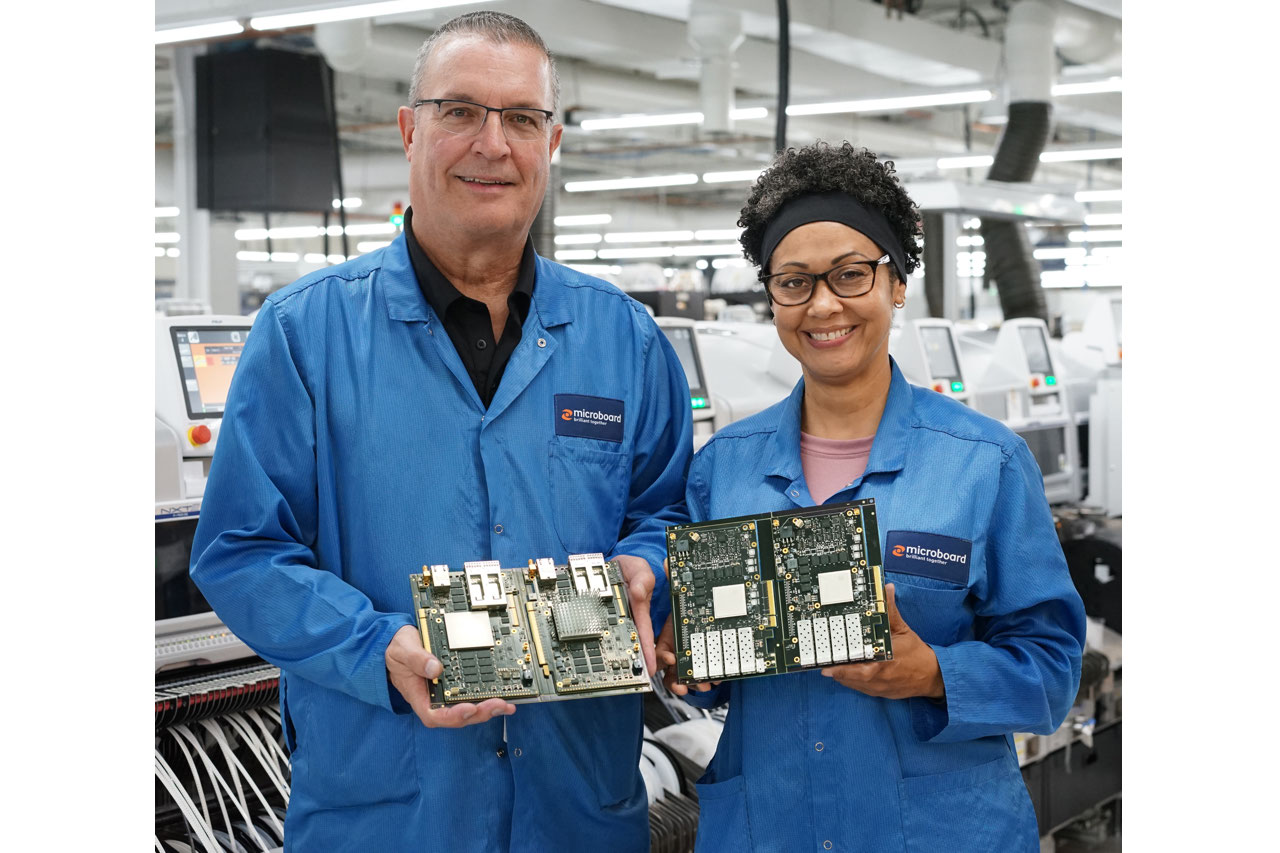

About Microboard

Microboard is an Electronics Manufacturing Services (EMS) provider of Printed Circuit Board Assembly and System Integration based in Seymour, CT. With four decades of experience in high mix/high reliability manufacturing using state-of-the-industry SMT lines, Microboard delivers superior service and quality results. Microboard specializes in RF technology and offers DFM/DFT, flying probe, and functional test including fixture design. Offering volume flexibility from prototype through production, Microboard can flex its supply chain to match demand variation. Our strategy is to deliver tailored service and solutions by focusing on a select customer base. ISO9001, ISO13485, and AS9100D, ITAR, IPC-A-610/ J-STD-001.