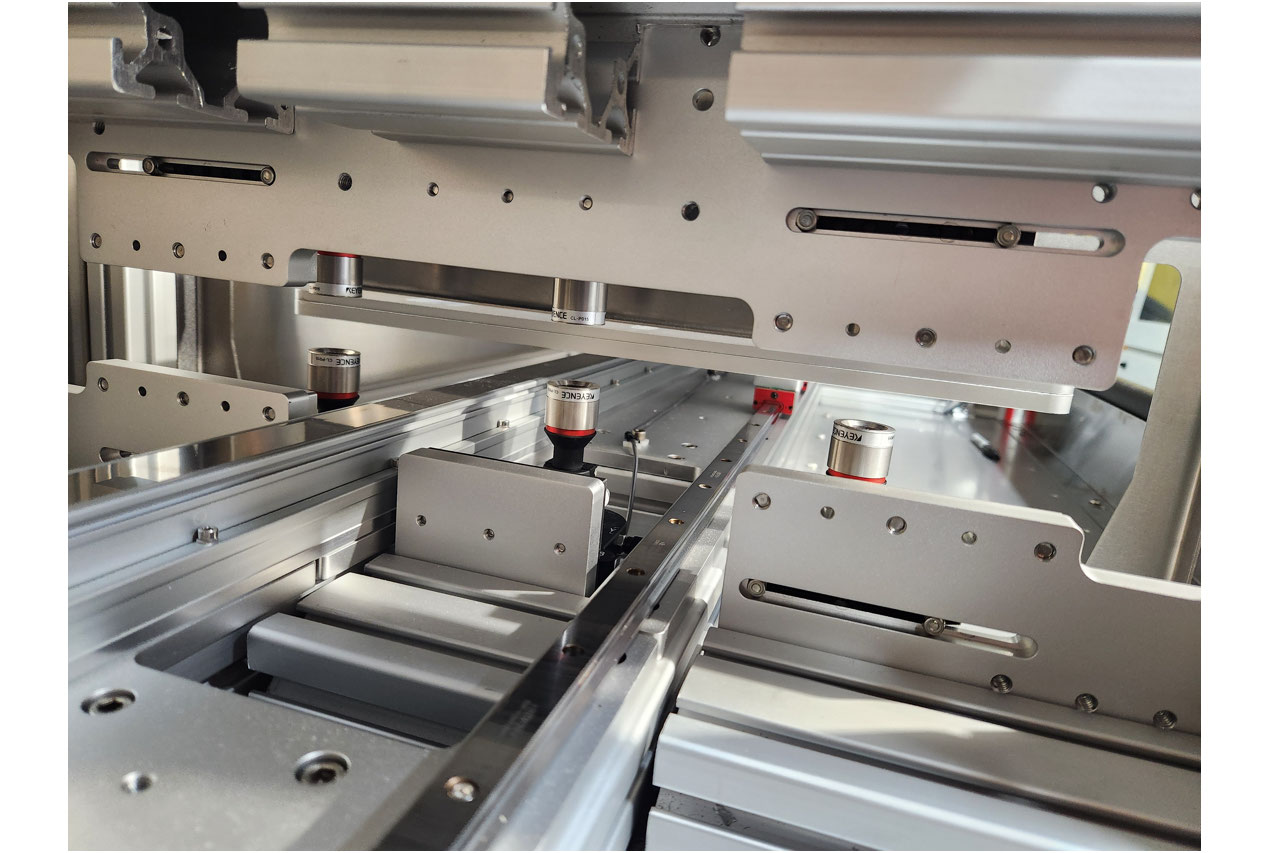

Bold Laser Automation, a leader in precision laser system design, proudly announces its latest metrology innovation: the Bold 3DS Series Confocal Thickness Measurement System integrated with Keyence CL Series laser sensors. Specifically engineered for sheet and web/foil materials, the Bold 3DS scanning systems deliver unmatched closed-loop accuracy and real-time data insights.

With continuous in-line and discrete off-line inspection, as well as real-time data plotting and archiving, this system is designed to meet critical FDA data requirements for industries requiring stringent quality control.

Designed for Versatility from Small Parts to Large Sheets

Capable of handling materials up to 1 M x 500 mm and executing rapid scans across multiple positions, the system combines flexibility with precision. Its customizable measuring configurations make it suitable for various industries, including electronics, medical devices, and filtration products.

Key System Highlights:

- Ultra-Precise Thickness Measurement: Depending on CL sensor selection, the system is designed for ±1 μm measurement accuracy.

- Integrated Data Solutions: Bold’s proprietary module provides seamless data storage, export to Excel, and real-time data analysis for QA/QC teams.

- Robust Motion Control: Featuring mapped stages, the system provides bidirectional repeatability within <±0.020 mm, crucial for high-precision applications.

- Customized Material Fixturing: Built from tool and jig plate, the system ensures materials remain stable well within the sensor’s range, maintaining accuracy.

- Safety and Vibration Control: Housed in a safety enclosure with seismic mounts, the system is designed to minimize vibration and ensure measurement stability within high-precision environments.

- Cost Effective: This machine offers high accuracy at a fraction of the cost of traditional measurement tools for manufacturers looking to enhance production value.

“We recognize the growing demands of today’s manufacturing industry, and this system—designed and built in the USA—provides a state-of-the-art solution that meets production speed, accuracy standards, and cost-effectiveness,” said Todd Lizotte, CEO and co-founder of Bold Laser Automation. “Our integration with Keyence’s measurement technology allows manufacturers to achieve unparalleled precision in real-time production monitoring.”

Seamless Keyence Integration

The 3DS scanning systems from Bold utilize Keyence’s CL Series software for easy setup and data backup, and continuous measurement scanning and histogram analysis. Paired with Bold’s proprietary integration suite, operators can control scan distances, transfer data in CSV format, and generate reports.

To learn more about Bold Laser Automation thickness measurement systems, read our blog: Where Precision Meets Affordability: Differential Confocal Laser Thickness Measurements.

About Bold Laser Automation

Bold Laser Automation specializes in advanced laser system design solutions for precision cutting, welding, measuring, and inspection applications. With a focus on high-performance manufacturing, reliability, and customer satisfaction, Bold solutions are trusted by industry leaders worldwide.

To access the latest book from Todd E. Lizotte, CEO and co-founder of Bold Laser Automation, see Laser Beam Shaping Applications, Second Edition.