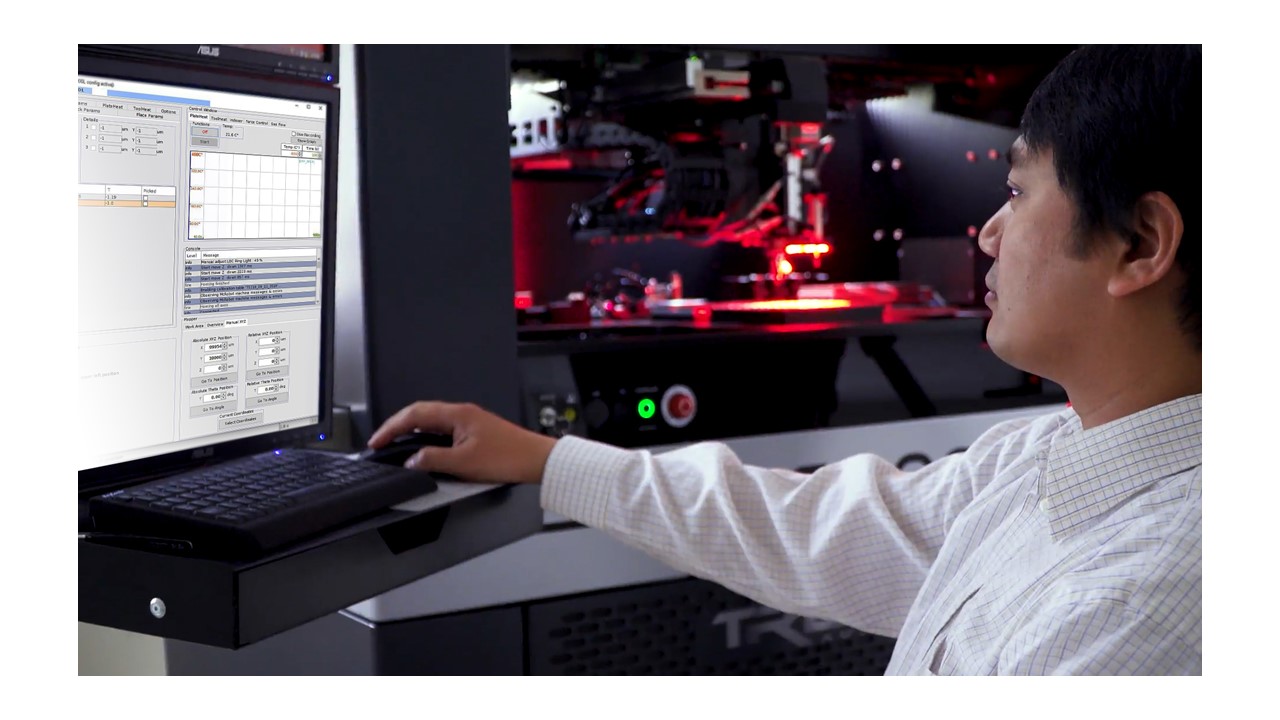

The DIE bonders from German specialist Tresky are equipped with a flexible, manual mode. This reduces the entry barrier for new users and makes it possible to achieve reliable die bonding results within a very short time. The manual mode is particularly suitable for applications that require quick iterations and adjustments while keeping highest precision.

“The manual mode of our DIE bonder offers unmatched flexibility and is perfect for research and development where precision and adaptability are crucial,” explains Daniel Schultze, Managing Director of Tresky GmbH. With just three clicks, operators can identify components and substrates without having to program time-consuming automated processes. “This enables fast, simple and repeatable handling and is ideal for the development of prototypes and small production volumes,” continues Schultze.

Operators can set up a pick-and-place process within minutes without extensive training. They simply select components visually, can use predefined dispensing patterns from the integrated library and comfortably can add forces and heating profiles. Multiple components can be selected simultaneously and processed efficiently with the same basic parameters. In addition to the user-friendly manual mode, Tresky’s DIE bonders also feature a fully automated mode optimized for higher production volumes. This mode supports complex, repeatable processes that can be seamlessly integrated into production lines to ensure continuous, efficient and scalable production.

“Our DIE bonders are the reliable solution for flexible, precise and efficient prototype development without the complexity and cost of conventional fully automated systems. In this way, we help our customers to shorten the development time of new products and optimize time-to-market,” emphasizes Schultze.

At PCIM Europe in Nuremberg, Tresky will present its DIE Bonder portfolio, including the Manual Operator Mode, from June 11 – 13 in Hall 5, booth 402.

About Tresky

Since 1980 the name TRESKY stands for the highest quality, unmatched flexibility with maximum reliability. Tresky GmbH is one of the world’s leading machine manufacturers for placement systems in the high-precision sector offering more than 40 years of experience in the semiconductor industry. The company is headquartered in Hennigsdorf near Berlin, in the middle of a technology park that is home to numerous highly specialized companies from the automation, electrical engineering, communications technology and

life science sectors. Quality “Made in Germany” – Tresky develops, produces and sells Die Bonders from its headquarters in Hennigsdorf. More information: www.tresky.de.