Luxinar, a world-renowned leader in laser technology, has launched its revolutionary LXR® ultrashort pulse (USP) laser platform which features a significant advancement in burst mode processing.

Ultra-precise control of energy deposition: The importance of burst mode

One of the most significant challenges in laser micromachining is achieving precise control over how laser energy is deposited into the material. Traditional single-pulse processing can lead to heat accumulation, which can cause unwanted effects like cracks, melting, or reduced processing quality. The LXR® platform addresses this challenge head-on with its innovative burst mode processing capability.

Burst mode processing for superior heat management

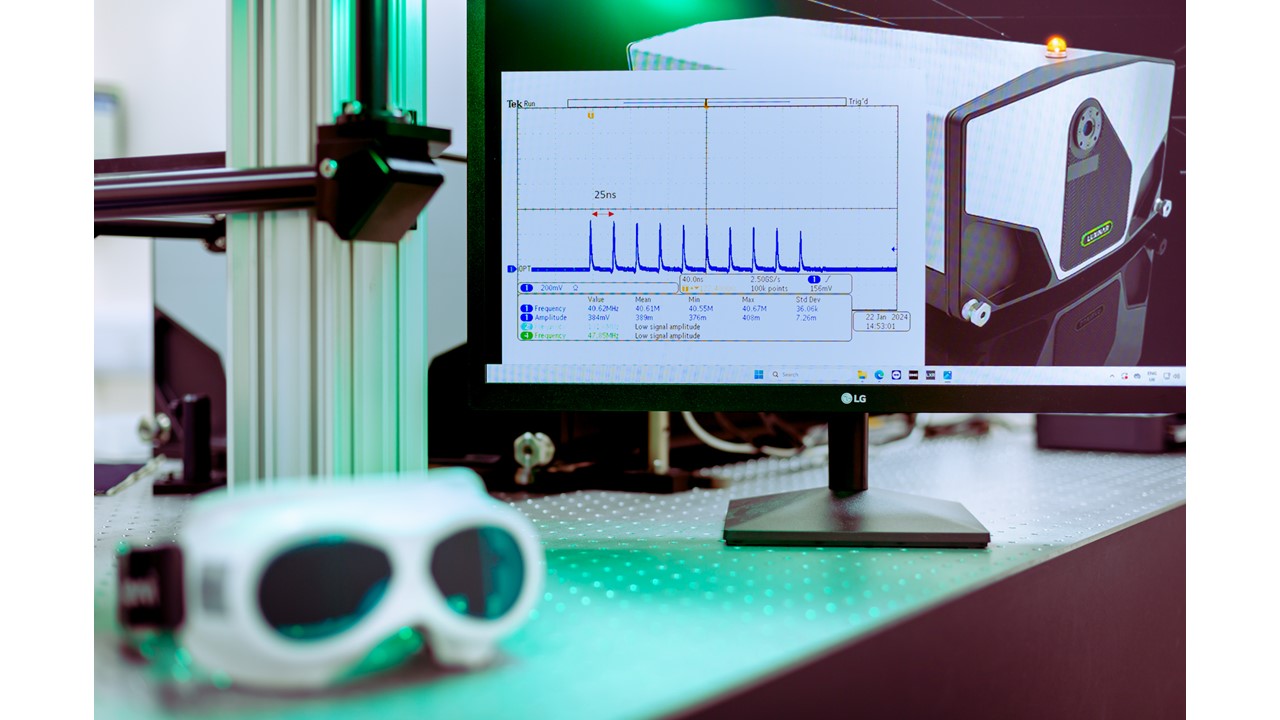

Burst mode processing involves delivering sequences (bursts) of several ultrashort laser pulses with inter-pulse delays precisely controlled for optimal material processing. These delays can be as short as 25 nanoseconds, creating a rapid sequence of pulses that interact with the material in a fundamentally different way compared to single pulses. Studies have shown that burst mode processing can significantly improve heat-related issues under certain conditions.

The theoretical concept behind burst mode processing is ablation-cooled material removal. By rapidly ablating material within the burst, the LXR® platform removes the heat energy and the ablated material. This keeps the target temperature lower, preventing heat accumulation and its detrimental effects on processing quality. However, achieving this cooling effect requires careful control of the inter-pulse delay. This delay needs to be shorter than the thermal relaxation time (𝜏₀) of the material, which is inversely proportional to its thermal diffusivity. In simpler terms, the heat needs to be removed before it has a chance to diffuse into the surrounding material significantly.

Burst mode processing offers another critical advantage: maintaining ablation efficiency even with reduced pulse energy per pulse. This is achieved by increasing the number of pulses within a burst. This approach overcomes the shielding effect caused by ablation-induced plasma. In traditional single-pulse processing, this plasma can block subsequent pulses, reducing overall processing efficiency. By using lower pulse energy and a higher number of pulses, the LXR® platform mitigates this shielding effect, ensuring effective material removal. However, it’s important to note that for intra-burst delays shorter than 20 nanoseconds, the shielding effect can still be significant. In such cases, subsequent pulses within the burst may be blocked by previously ablated material.

This patented technology, where the laser can emit up to 170 pulses separated by 25 nanoseconds with total burst energy equal to five times the single pulse energy, translates into:

- Precise ablation: Enables clean and controlled material removal for intricate features.

- Minimal thermal damage: Minimises heat-related effects for high-quality results.

- Exceptional beam control: Delivers superior processing accuracy and repeatability.

“Luxinar has earned a well-deserved reputation for producing robust and reliable laser sources,” said Antonio Raspa, Solid State Laser Product Manager at Luxinar. “The LXR® platform upholds this tradition by ensuring optimal uptime and productivity, backed by Luxinar’s exceptional customer support and service.”

To learn more, visit www.luxinar.com.