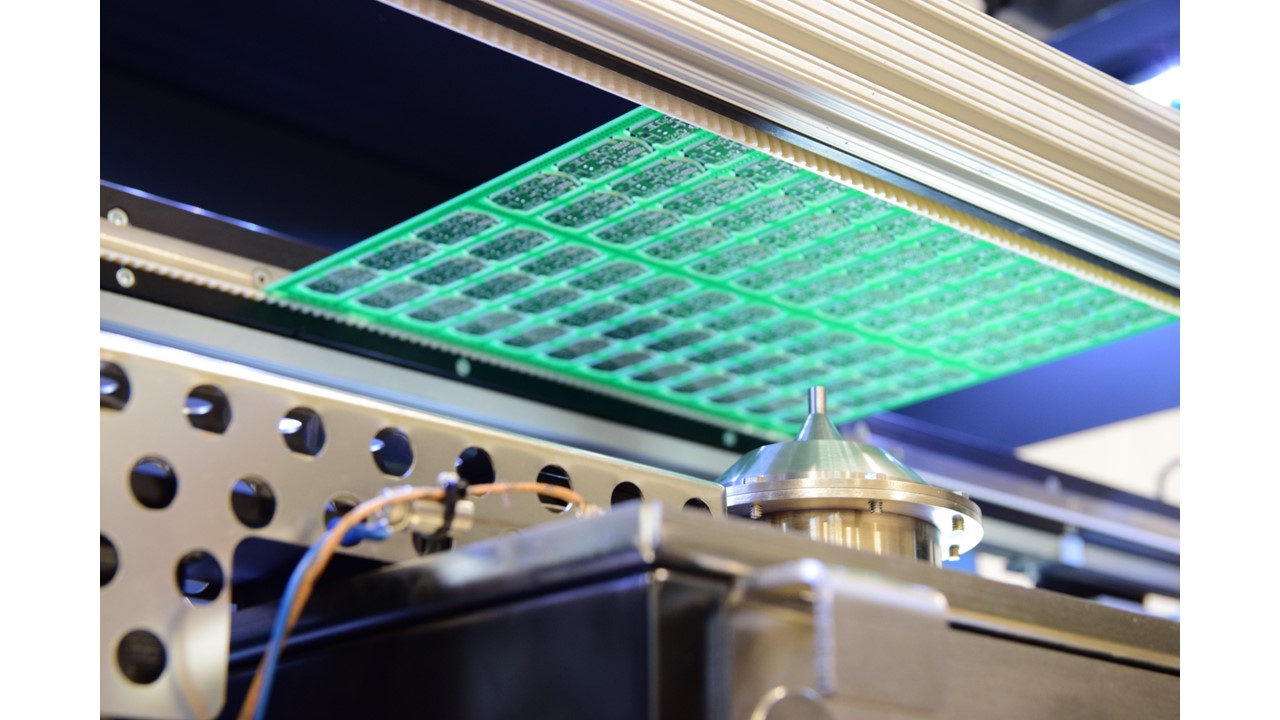

Hentec Industries/RPS Automation, a leading manufacturer of selective soldering, lead tinning and solderability test equipment, is pleased to announce that Daicel Safety Systems has finalized the purchase of a Hentec/RPS Vector 300 selective soldering system. The Vector 300 is a compact selective soldering system with a small factory floor footprint and is ideally suited for 24/7 production basis, the same as the Vector 460 and Vector 600 models. The Vector 300 is fully lead-free compatible and features an integrated computer with unlimited program storage, integrated system software, witness camera and auto fiducial correction. Available in either standalone or SMEMA in-line configurations, the Vector 300 is offered with topside preheat, spray or drop-jet fluxer, dual flux nozzles, and custom or wave solder nozzles. The Vector 300 is UL and CE compliant and carries both a two-year system warranty and a four-year solder pot warranty.

About Daicel Safety Systems

Headquartered in Mesa, Arizonia, Daicel Safety Systems is a division of DSSA Incorporated and is a manufacturer of critical life-saving devices including automotive airbag systems, medical devices, fire suppression systems, law enforcement non-lethal devices, and many other applications all rely on the extremely high-reliability of our products to save lives daily. For more information, please visit: www.daicelsse.com.

About Hentec Industries

Hentec Industries/RPS Automation is a manufacturer of automated selective soldering, component lead tinning, and solderability test equipment for electronics and electronic component manufacturing, assembly, and distribution. Hentec/RPS has been advancing automated soldering and lead finishing technology for defense, aerospace, automotive, contract manufacturers and micro-electronics component manufacturers since the early 90’s. All Hentec/RPS products are designed and manufactured in Newman Lake, Washington. For more information, please visit us at www.rpsautomation.com.