The triumph of selective soldering is a representation of developments in electronics production. The applications are becoming more and more diverse and the component variants are increasing. No other process can meet this range of challenges better than selective soldering. And no supplier offers a broader portfolio than market leader Ersa.

With the VERSAFLOW ONE, system supplier Ersa presents the entry into the excellence class of selective soldering. With the F-series, it offers inline technology at the price of a batch machine. The ONE is the first system in its class to offer the option of two pots per soldering module, the distance between which can be adjusted manually in the transport direction. This makes it the ideal choice for small and series production of simple assemblies that require reliable technology with high throughput. Ersa presented the new X-series at Productronica 2023 in Munich: the VERSAFLOW ONE with x-variable axis system, optionally also available with a 2-stopper solution. A special added value for customers that significantly increases throughput – and a unique feature in the entry-level class. Up to eight assemblies (max. dimensions 350 x 508 mm) and up to four assemblies (max. dimensions 508 x 508 mm) can be processed simultaneously in the machine, making the VERSAFLOW ONE XFF a genuine high-speed machine.

The VERSAFLOW ONE incorporates decades of know-how from the market leader in the form of proven hardware and intuitive software (ERSASOFT 5). The ONE has all the features that have made Ersa selective soldering the leading technology in the industry over many years. It has a 3 mm pin chain/roller conveyor and program-controlled width adjustment as standard for maximum flexibility and performance. The flux module relies on the proven multidrop system with one or two flux heads and numerous options. The precision of the multidrop fluxer enables almost any conceivable geometry.

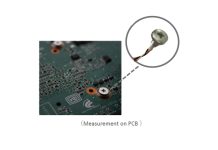

The basic version of the preheater is equipped with a short-wave IR heating module from below. Top heating with convection in the preheater is available as an option. Contactless monitoring of the PCB temperature in the preheater guarantees maximum process reliability. Features such as automatic nozzle activation or solder wire feed are also on board. Of course, connection to the KE CONNECT digital service platform is also available on request, making the VERSAFLOW ONE a safe investment for future requirements in digitized electronics production.

More under www.kurtzersa.com