As the industry expands rapidly, manufacturers require conveyor systems that can handle higher volumes and accommodate various soldering applications. The Heavy-Duty Finger Conveyor option being introduced by Electrovert is designed to address the increasing demands of PCB production in terms of throughput capability and process flexibility.

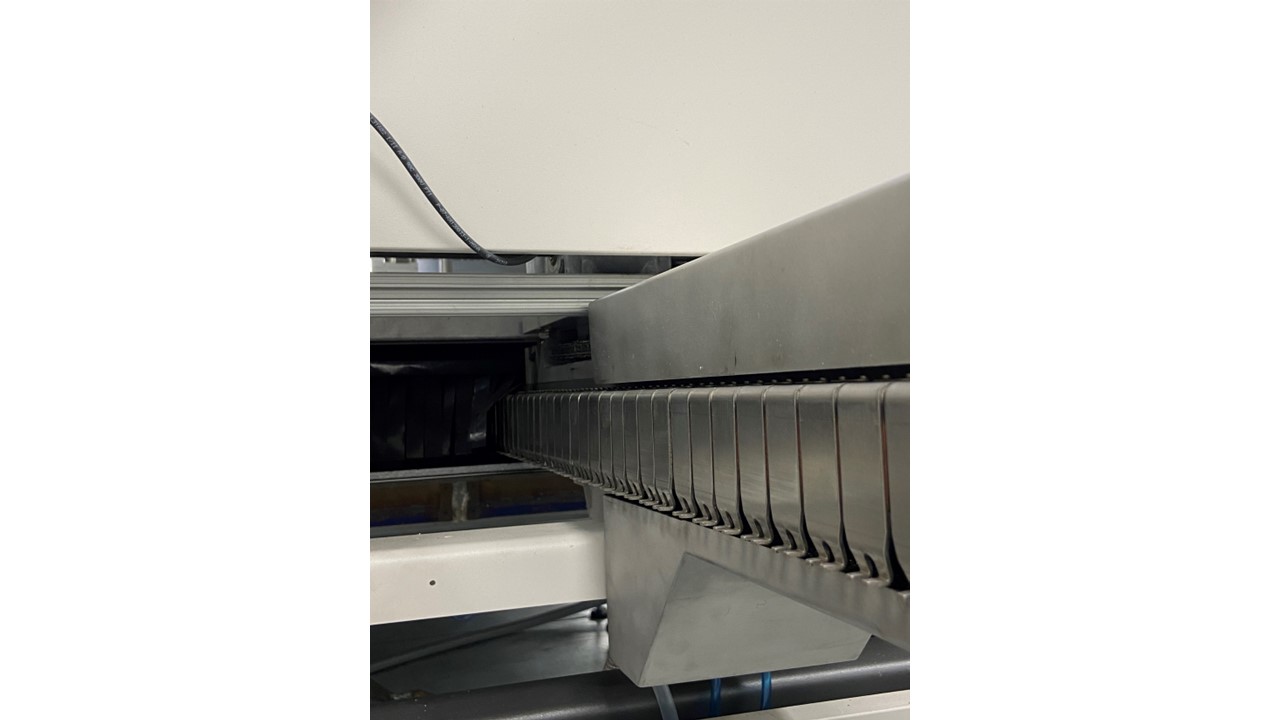

The Heavy Duty Conveyor is designed to handle heavier loads of up to 91 kg (200 lb) while still maintaining the benefits of a single continuous conveyor. The use of titanium universal V/L fingers with a choice of 3mm or 6mm L, along with precision linear bearing support cross shafts and fine-pitch screw shafts are robust with excellent parallelism for the conveyor. The high-strength hard-coat anodized aluminum extrusion used in the rail and tunnel support structure are field proven in demanding production environments for its durability and stability.

“Customers can increase their line throughput without sacrificing yields,” said Greg Calvo, Electrovert Product Manager. “The Heavy Duty Conveyor increases efficiency and productivity, reduces downtime and improves product quality.”

Electrovert’s Heavy Duty Conveyor option is an excellent solution for demanding production environments that require a robust and reliable conveyor system that can handle heavier weights and higher throughput rates without sacrificing yields or increasing the risk of damage or misalignment.

Electrovert is a brand of ITW EAE, a division of Illinois Tools Works, Inc. They are the largest manufacturer of wave soldering and cleaning equipment for the electronics industry.

ITW EAE brings together world-leading brands of electronics assembly equipment including MPM, Camalot, Electrovert, Vitronics Soltec, and Despatch. For more information visit www.itweae.com.