After the water-based flux EO-G-006 was already introduced this year, the german flux specialist expanded the product range of ecologically degradable fluxes with EO-G-005 and EO-G-007.

“The two new, water-based fluxes EO-G-005 and EO-G-007 represent the starting signal for our product innovations in the second half of the year,” expresses Markus Geßner, Marketing and Sales Manager at Emil Otto GmbH. Until productronica in November 2023, Emil Otto plans to present further innovative ideas around soldering and cleaning of assemblies.

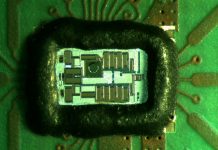

EO-G-005 was specially developed for use in wave soldering machines and has a relatively high activity despite the low solids content of only approx. 4 %. It is applied by means of a spray fluxer. “We recommend that assemblies soldered with water-based fluxes that are subsequently to be painted or encapsulated be tested beforehand for compatibility between the coating materials and the flux residues. In addition to the suitability test according to DIN 61190-1-1, the flux EO-G-005 also passed our internal EO in-house standard EO-STV-2016-02-01, which is based on the rapid test procedure for selective, dipping and manual soldering fluxes according to Fraunhofer (ZVE),” Geßner explains. This means that, compared to other conventional fluxes, the flux residues of EO-G-005 are significantly less critical after wave soldering and can be rated as non-corrosive.

Emil Otto will also be presenting the EO-G-007 No Clean flux, which is also suitable for wave and selective soldering of printed circuit boards. The flux contains organic, halogen-free, activating additives specially adapted for soldering processes. The new development was developed in a combination with lead-containing and lead-free solders that is specially adapted to the thermal requirements of the soldering process. In addition, EO-G-007 is based on a novel formulation to stabilize and improve the application process compared to conventional water- or partial water-based fluxes. With a solids content of 7%, Emil Otto continues to serve the high demand for water-based fluxes with a higher solids content.

With regard to the Green Line fluxes, it is important to Geßner to point out not only the ecological added value of the water-based products, but also the economic advantages. “Due to their high ecological compatibility, these fluxes are not subject to the class of hazardous goods and do not pollute the environment. Our Green Line products can therefore be transported, handled and stored in the conventional way. Simple, conventional storage in particular thus represents considerable added value,” Geßner emphasizes.

About Emil Otto

Since 1901 “Emil Otto” stands for top quality. As owner-managed company, Emil Otto is committed to the development and manufacturing of high-quality fluxing agents. In particular the fluxing agents for electronics production, strip tinning, cooler construction as well as for galvanizing are used by market leaders at home and abroad.

Over the years, reliable products and a high level of customer care have become the signature. The manufacturing takes place in accordance with the latest standards, the quality- and environmental management system has been certified for many years. Emil Otto responds with high flexibility to customer requests. Special products or product adaptations are developed and implemented in collaboration with system manufacturers and institutes. More information: www.emilotto.de/?lang=en.