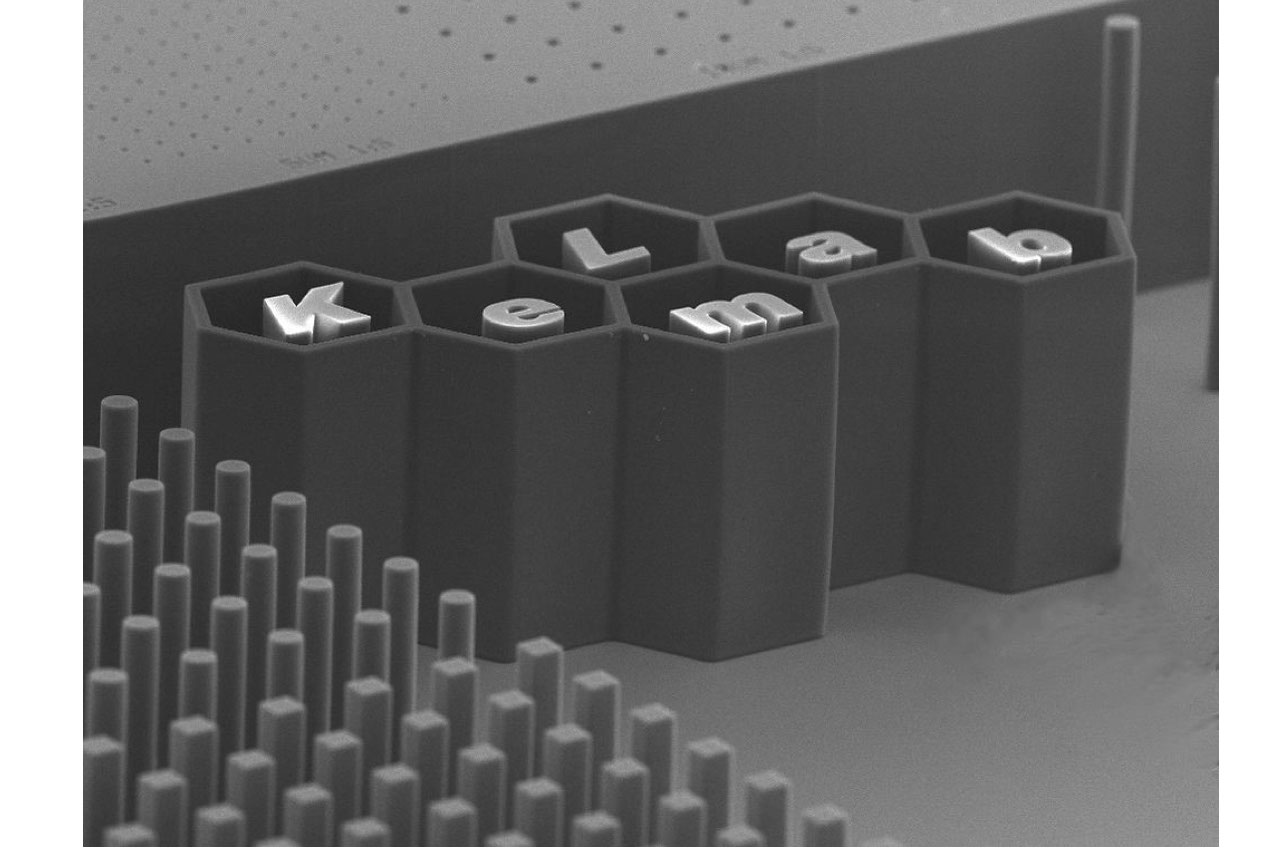

KemLab Inc., a pioneering developer of advanced materials for microelectronics and MEMS applications, offers HARE SQ™, a state-of-the-art negative tone epoxy photoresist designed to revolutionize the world of polymeric MEMS, microfluidics, micromachining, and other permanent microelectronic applications.

HARE SQ sets a new standard in the industry, offering superior performance and enhanced features that make it the go-to solution for microfabrication needs. This cutting-edge photoresist is highly sensitive to NUV, i-line and broadband wavelengths, catering to a diverse range of lithographic processes. With film thicknesses ranging from 2-200 microns, HARE SQ opens up a multitude of possibilities for permanent applications, including MEMS, microarrays, VSCEL, waveguides, antennas, sensors, microfluidics, PDMS molding, pixel walls, fluidic channels, inkjet nozzles, and spacers.

Five Reasons to Switch to HARE SQ Negative Epoxy:

- Plug-n-Play Compatibility: HARE SQ seamlessly integrates with established SU-8 lithographic processes, offering an effortless transition from SU-8 negative epoxy to KemLab’s HARE SQ. Embrace innovation without the need for extensive process overhauls.

- Competitive Pricing: HARE SQ is designed to be highly competitive in the market, offering better quality at a lower cost.

- Superior Raw Materials: The foundation of excellence lies in premium materials. HARE SQ uses a superior quality resin, specially engineered for the microelectronics industry. This innovative resin manufacturing process results in a cleaner, more consistent negative epoxy photoresist with reduced particle count, improved transparency, and fewer microbubbles.

- Enhanced Optical Transparency: HARE SQ resin material boasts exceptional visual clarity, reduced yellowing, and improved transparency compared to SU-8. These features result in enhanced light transmission and superior resistance to oxidative yellowing, ensuring the longevity of microelectronic applications.

- Application-Focused Quality Control: Understanding the diverse needs of the microfluidic and optical industries, KemLab has implemented value-added testing to address specific application requirements. HARE SQ undergoes rigorous quality control measures to ensure optimal performance in various microfabrication processes.

“At KemLab, we are dedicated to pushing the boundaries of innovation and continuously improving our products to meet the evolving demands of the microelectronics industry,” said Jeremy Golden, General Manager at KemLab Inc. “HARE SQ is a testament to our commitment to excellence, offering outstanding features and compatibility that will empower our customers to achieve new heights of success in their microfabrication endeavors.”

Experience the power of HARE SQ and elevate your microelectronics applications to new levels of performance and precision.

For inquiries and more information, visit kemlab.com or get in touch with KemLab’s expert team today.

About KemLab Inc.

KemLab is a pioneering developer and manufacturer of advanced materials for microelectronics and MEMS applications. With a focus on innovation, quality, and customer satisfaction, KemLab aims to provide cutting-edge solutions that drive progress in the microfabrication industry.