Nordson TEST & INSPECTION today announced that it will exhibit at SMTConnect, scheduled to take place May 9-11, 2023 in Nuremberg, Germany. The company will feature the multi-award-winning CyberOptics SQ3000™ Multi-Function system for AOI, SPI and CMM, along with the X3 AXI system in Hall 4, Stand 216 with SmartTec.

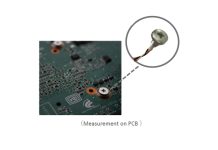

The CyberOptics SQ3000 Multi-Function system, deemed best-in-class, can identify critical defects and measure critical parameters, in order to fix what can be found and control what can be measured. In addition to AOI and SPI applications, highly accurate coordinate measurements can be attained faster than a traditional Coordinate Measurement Machine (CMM) – in seconds, not hours.

Powered by proprietary Multi-Reflection Suppression® (MRS®) sensor technology, the 3D SQ3000 all-in-one system offers an unmatched combination of high speed, high resolution and high accuracy. The MRS sensor meticulously identifies and rejects reflections caused by shiny components and surfaces, making it an ideal technology solution for a wide range of applications, particularly high-end and challenging applications with stringent quality requirements.

“Since the close of the acquisition last November, CyberOptics systems have complemented Nordson TEST & INSPECTION ‘s broad portfolio with its world-leading optical inspection and metrology technology powered by MRS technology,” said Perry Duffill, VP of Nordson TEST & INSPECTION. “Having established a leading position in the X-ray inspection systems market, I am pleased that our fundamental expertise in X-ray technology is coupled with industry leading automated optical technology to improve our customers yields, processes and productivity. Plus, our application experts can ensure seamless transitions from one system to another, enabling the entire electronics manufacturing process in Nordson’s SMT and semiconductor markets to be designed with interlocking systems.”

The AXI X-Series is a dedicated autonomous high-speed inline X-ray inspection system for the inspection of PCB assemblies in single or multi panels or in workpiece carriers. The system offers market-leading inspection speed and is ideal for electronics manufacturing with high throughput requirements. The X series is characterized by a high degree of flexibility and configurability. Microfocus X-ray tube, in-house detector from the Quadra series from Nordson MXI and the latest 3D analysis architecture as well as a comprehensive software environment guarantee complete traceability via customer-specific MES and SECS/GEM interfaces.

For more information, visit cyberoptics.com and nordson.com.

About Nordson TEST & INSPECTION

Nordson TEST & INSPECTION offers its customers a robust product portfolio, including Acoustic, Optical and Manual X-ray Inspection, Autonomous X-ray Inspection, X-ray Component Counting and Nordson X-ray Technologies. Nordson TEST & INSPECTION is uniquely positioned to serve its customers with best-in-class precision technologies, passionate sales and support teams, global reach, and unmatched consultative applications expertise.

About Nordson

Nordson Corporation (Nasdaq: NDSN) is an innovative precision technology company that leverages a scalable growth framework through an entrepreneurial, division-led organization to deliver top tier growth with leading margins and returns. The Company’s direct sales model and applications expertise serves global customers through a wide variety of critical applications. Its diverse end market exposure includes consumer non-durable, medical, electronics and industrial end markets. Founded in 1954 and headquartered in Westlake, Ohio, the Company has operations and support offices in over 35 countries.