Indium Corporation® is proud to showcase its innovative products and expertise for the rapidly evolving electric vehicle manufacturing and e-Mobility market, including cutting-edge high-reliability alloys, at productronica China, April 13-15, in Shanghai.

With its significant automotive industry expertise and an award-winning portfolio of proven products, Indium Corporation will feature its Rel-ion™ suite of electrical, mechanical, and thermal solutions which are designed to be reliable, scalable, and proven materials to reduce electric vehicle (EV) manufacturers’ time to market.

More than three million EVs are on the road with Indium Corporation’s Rel-ion products. Rel-ion material solutions deliver reliability by:

- Eliminating non-wet opens and head-in-pillow defects

- Preventing dendritic growth by meeting stricter surface insulation resistance requirements

- Preventing solder delamination with precise bondline control and increased creep and fatigue resistance

- Reducing hot spots-induced voiding through improved thermal efficiency

Some of the Rel-ion suite products include:

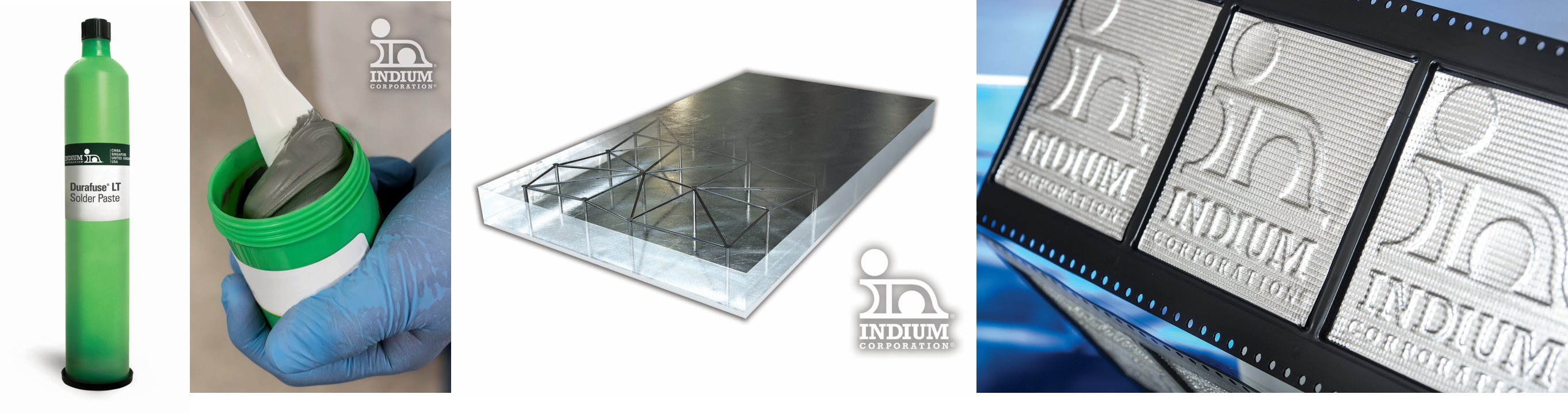

- Award-winning Durafuse® LT, a novel solder paste mixed alloy system with highly versatile characteristics that enable it for energy savings, high-reliability, low-temperature, step soldering, and assemblies with large temperature gradients. It also provides superior drop shock performance as compared to conventional low-temperature solders, outclassing BiSn or BiSnAg alloys, and performing better than SAC305 with optimum process setup.

- The Indium8.9HF Solder Paste Series, an industry-proven solder paste series that delivers no-clean, halogen-free solutions designed to enhance electrical reliability, improve stability during the printing process, and deliver low-voiding for high-reliability automotive electronics.

- InFORMS®, reinforced solder alloy fabrications, improve mechanical and thermal reliability, and are specifically designed to produce consistent bondline thickness for power module applications. They also address specific challenges for the power electronics industry by providing an enhanced material for the development of more reliable and higher performance modules.

- Heat-Spring® solutions, ideal for TIM2 applications, are a compressible interface between a heat source and a heat-sink. These indium-containing TIMs offer superior thermal conductivity over non-metals—with pure indium metal delivering 86W/mK.

To learn more about why over 3,000,000 electric vehicles are on the road with Indium Corporation’s proven materials, visit them at booth N4.4102 or at www.indiumchina.cn.

About Indium Corporation

Indium Corporation® is a premier materials refiner, smelter, manufacturer, and supplier to the global electronics, semiconductor, thin-film, and thermal management markets. Products include solders and fluxes; brazes; thermal interface materials; sputtering targets; indium, gallium, germanium, and tin metals and inorganic compounds; and NanoFoil®. Founded in 1934, the company has global technical support and factories located in China, Germany, India, Malaysia, Singapore, South Korea, the United Kingdom, and the U.S.

For more information about Indium Corporation, visit www.indium.com or email jhuang@indium.com. You can also follow our experts, From One Engineer To Another® (#FOETA), at www.linkedin.com/company/indium-corporation/ or @IndiumCorp.

About productronica China

productronica China showcases the entire value chain in electronics production in all industrial sectors. Held at the Shanghai New International Expo Centre (SNIEC), it has been one of the most important events in Asia since 2002. www.productronicachina.com.cn