Automation continues to transform numerous industries, raising productivity by improving both the production rate and quality. Ultimately, more good units are produced. However, many businesses value human skills such as dexterity and visual acuity for tasks such as inspection, particularly when items are difficult to handle – such as moulded plastic parts, or textiles – and defects can be seen or felt easily.

This can present companies with a dilemma. Full automation may be technically feasible, although excessively expensive. If production volumes or the unit price of the produced items is low, the projected return on investment in automation may be unacceptable.

Small SCARA robots that are sized to handle light picking and packing tasks are available at affordable prices. They can be deployed cost-effectively alongside human inspectors to help raise productivity and quality. A little imagination may be required to adapt the sequence for best results.

Increase Output and Quality

Yamaha recently helped a customer producing injection-moulded components for industrial applications to overcome a quality-control issue that had held back productivity. The solution introduced a SCARA robot from Yamaha’s YK-XE series, with the RCXiVY2+ vision system and YRG series electric gripper, to support operators inspecting the mouldings. Assisted by the robot, inspectors were empowered to detect moulding defects and accurately trace the cause so that it could be fixed quickly. In addition to improving quality, bringing the robot into the process also helped increase the production rate.

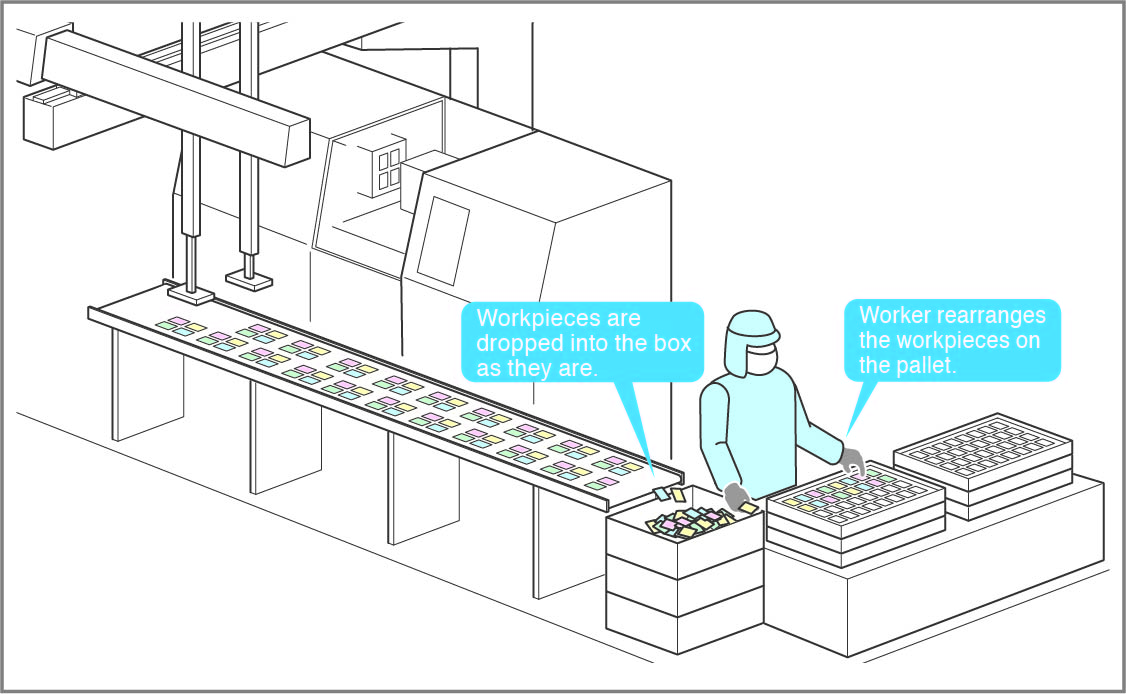

The quality-control problem stemmed from the fact that a single human operator had been responsible for inspecting and packing items produced by a moulding machine that has multiple cavities. A take-out robot removes all items from the machine, at the end of each moulding cycle, and places them on a conveyor. The conveyor drops all the mouldings into a box, from which the operator picks one at a time and then inspects and palletises each one (figure 1).

In this situation, it’s impossible for the operator to connect any recurring defects back to the originating cavity in the moulding machine. This created the potential for large numbers of faulty units to be produced before the cause can be identified, which wastes resources and also increases opportunities for defective units to escape from the factory.

Improving quality control would require identifying the individual moulding cavity from which any defective part had originated. This is beyond the capabilities of a lone operator, under pressure to pick and pack the items at a speed compatible with the production rate. Another approach could be to inspect each moulding as ejected from its cavity, before being placed on the conveyor alongside the other items. This would likely require multiple inspectors, adding to the overall manufacturing costs.

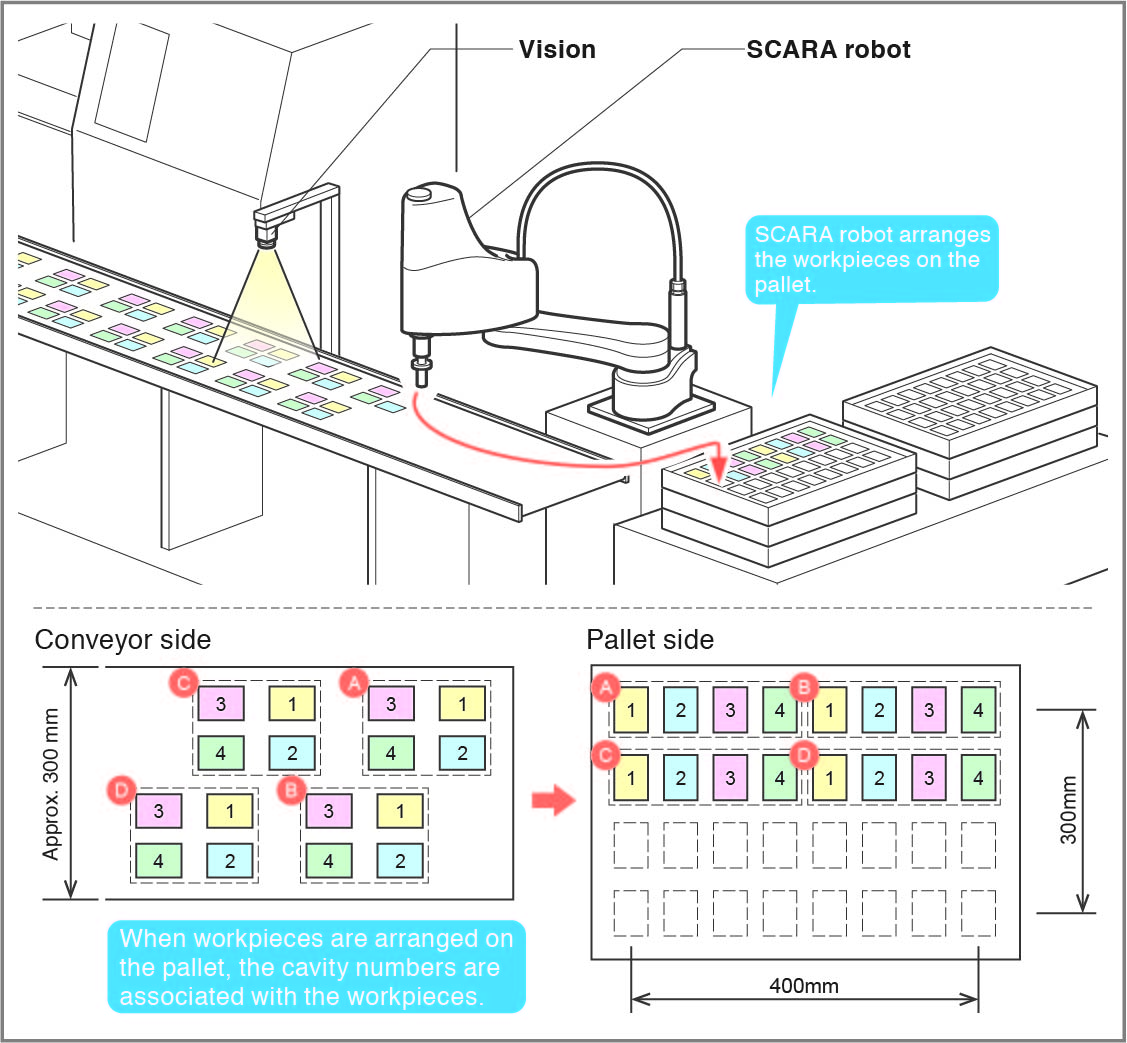

Yamaha’s YK-XE SCARA offered a solution by enabling items to be palletised at high speed, picking directly from the conveyor. This allowed them to remain in the same order they emerged from their cavities. As a result, any item inspected and found to be faulty can be directly linked to the originating cavity thereby allowing the cause to be fixed quickly. The integrated RCXiVY2+ vision system can simultaneously track the position and orientation of up to 100 items travelling on the conveyor, to help the robot pick and palletise each moulding quickly and accurately (figure 2).

The YK-XE SCARA series comprises robots rated for payloads up to 10kg and offers a choice of arm lengths from 400mm to 710mm. While these robots are conceived to help factories introduce robot technology at affordable cost, they provide valuable features including generous wiring and pneumatic tubing for controlling end effectors. These can be routed through-shaft and through-cap, which enhances convenience and protects against breakage and disconnection. Arm acceleration and deceleration are automatically optimised according to the payload weight, to ensure maximum speed and prevent vibration thereby permitting superior accuracy. Other series in the Yamaha SCARA family include the omnidirectional YK-TW, which allows large pallet sizes.

Vision System Example

Another case involved a company producing large numbers of an electronic gauge used in automotive instrumentation. The gauge comprises a populated circuit board, pointer mechanism, a screen-printed dial face, and electrical connectors (figure 3). The team wanted to increase production by using SCARA robots to quickly pick and palletise the assembled units coming off the production line. The pallets are then transported to the next stage of manufacture.

The team knew that a vision system would be needed to ensure the components were correctly aligned in order to be palletized satisfactorily. From previous experience, they understood that integrating a machine-vision system as part of an automated handling solution was expensive and time consuming. Also, their previous foray into the technology had required specialist knowledge. On the current occasion, their machine-vision specialist happened to be seconded to another division at the time. Ending the secondment to handle this project was not an option.

The RCXiVY2+ robot vision system helped overcome the challenge. Management of the camera and vision processing is integrated within the RCX340 controller, which also hosts the robot application. The camera can be attached to the robot (figure 4) or mounted on a separate fixture. Yamaha’s system has dedicated vision instructions simplify programming. The team had the system up and running extremely quickly. In fact, the integration took about one fifth of the time typically needed when using conventional machine-vision technology. The setup can be completed in as little as eight minutes after power-on and auto calibration is provided. In addition, a dedicated bus line allows high data speeds thereby avoiding the latency that can impair the performance of conventional systems.

Robot vision can enhance many industrial processes In addition to tracking items to be picked from a conveyor and helping to orientate parts for palletising, and affixing labels to components. In this case, the robot can position the labels consistently in the same place and orientation on each item even if the incoming workpieces are irregularly spaced or oriented.

Vision can also assist processes such as applying dispensable materials like adhesive, liquid gasket, or sealant, by detecting if the workpiece is skewed and enabling the application path to be corrected. Generally, vision can enhance assembly tasks such as screwdriving, by quickly detecting hole positions to assist fastening, and can help ensure correct alignment of parts before insertion or joining.

Conclusion

The affordable cost of small SCARA robots for light production and packaging tasks allows more flexible approaches to introducing automation in industrial activities. While speed, accuracy, and reliability are well known robot strengths, with thoughtful application they can also provide information that can help improve process control and keep production flowing: another way to boost productivity. Also, by making flexible automation more affordable than ever, small SCARA robots can be used cost-effectively in low-volume, low-cost scenarios.

Machine vision is a critical capability in many handling and packaging applications. Bringing control of vision inside the robot domain, with dedicated vision instructions, can accelerate and simplify integration and enhance system performance.

Companies of all sizes can now infuse robots into their activities, using them to work alongside and assist human operators as well as accelerate repetitive or mundane tasks.

For more information, please visit www.yamaha-motor-robotics.eu.