Heraeus Electronics is pleased to announce the release of its new Microbond® SMT660 Innolot® 2.0 no-clean printing T4 solder paste. The new high reliability, high performance solder paste provides a competitive TCO offering. Based on Heraeus Electronics’ proven experience, Innolot 2.0 allows a wide process window, enabling soldering in air with a low defect rate. Additionally, it is designed to offer an optimized formulation for lower costs.

The requirements for mobility are changing worldwide. Electrification and automation of vehicles lead to high demand for cost- and performance-efficient materials. These are required to meet the increasing need for safety and support systems such as advanced driver assistance systems, increasingly intelligent control units, as well as in-car entertainment systems. The increasing demand is accompanied by harsher requirements for components and materials as well as TCO challenges.

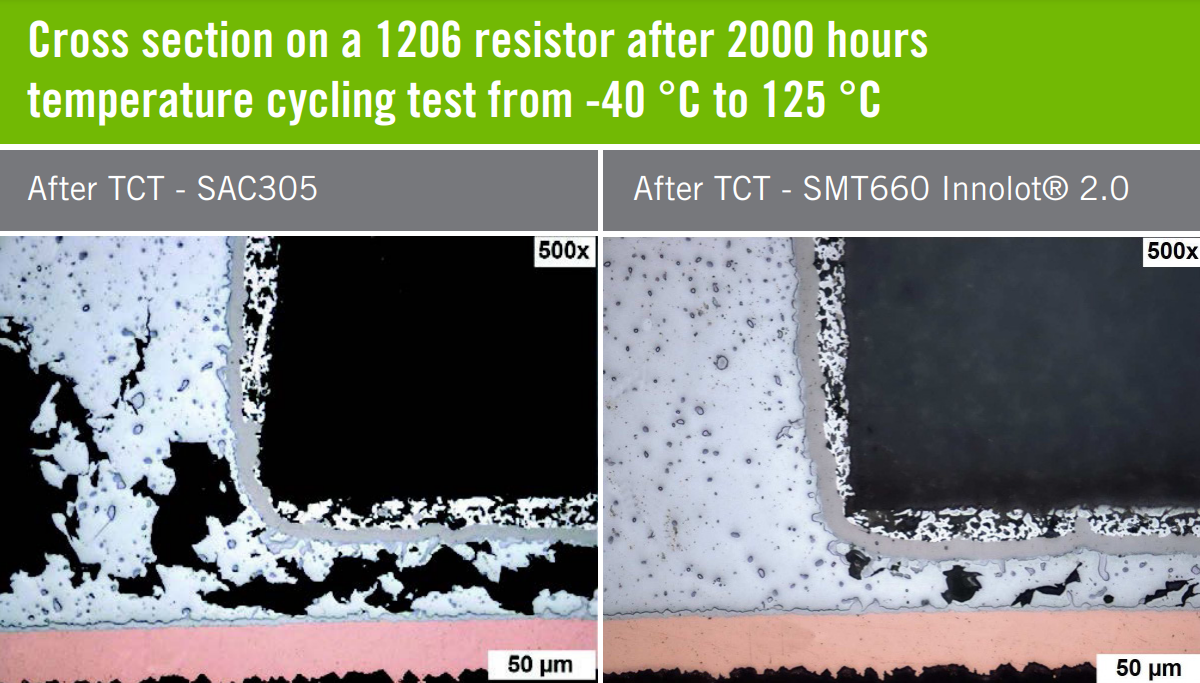

With its new approach through Microbond® SMT660 Innolot® 2.0 for highly reliable and cost-effective solder alloys for automotive applications, Heraeus Electronics introduces the ability to maintain a competitive Total-Cost-of-Ownership, while fulfilling emerging requirements. The next generation of Innolot® alloy offers reduced cost while maintaining the well-known features of higher creep resistance, resulting in longer product life cycles at higher operating temperatures. The Microbond® SMT660 Innolot® 2.0 solder paste performs in the air without additional N2 during reflow, while keeping defect rates low, reducing your TCO.

The flux Microbond® SMT660 uses an acrylic based synthetic resin eliminating potential batch-to-batch variations when using natural raw materials. Due to its low impurities and the flux design, a high SIR performance is achieved. As a result, SMT 660 reduces the risk for electrochemical migration. The combination of the flux with Innolot® or Innolot® 2.0 alloy delivers a solder paste with superior reliability – especially in miniaturized systems in the automotive industry.

To learn more about Heraeus Electronics, visit www.heraeus-electronics.com.