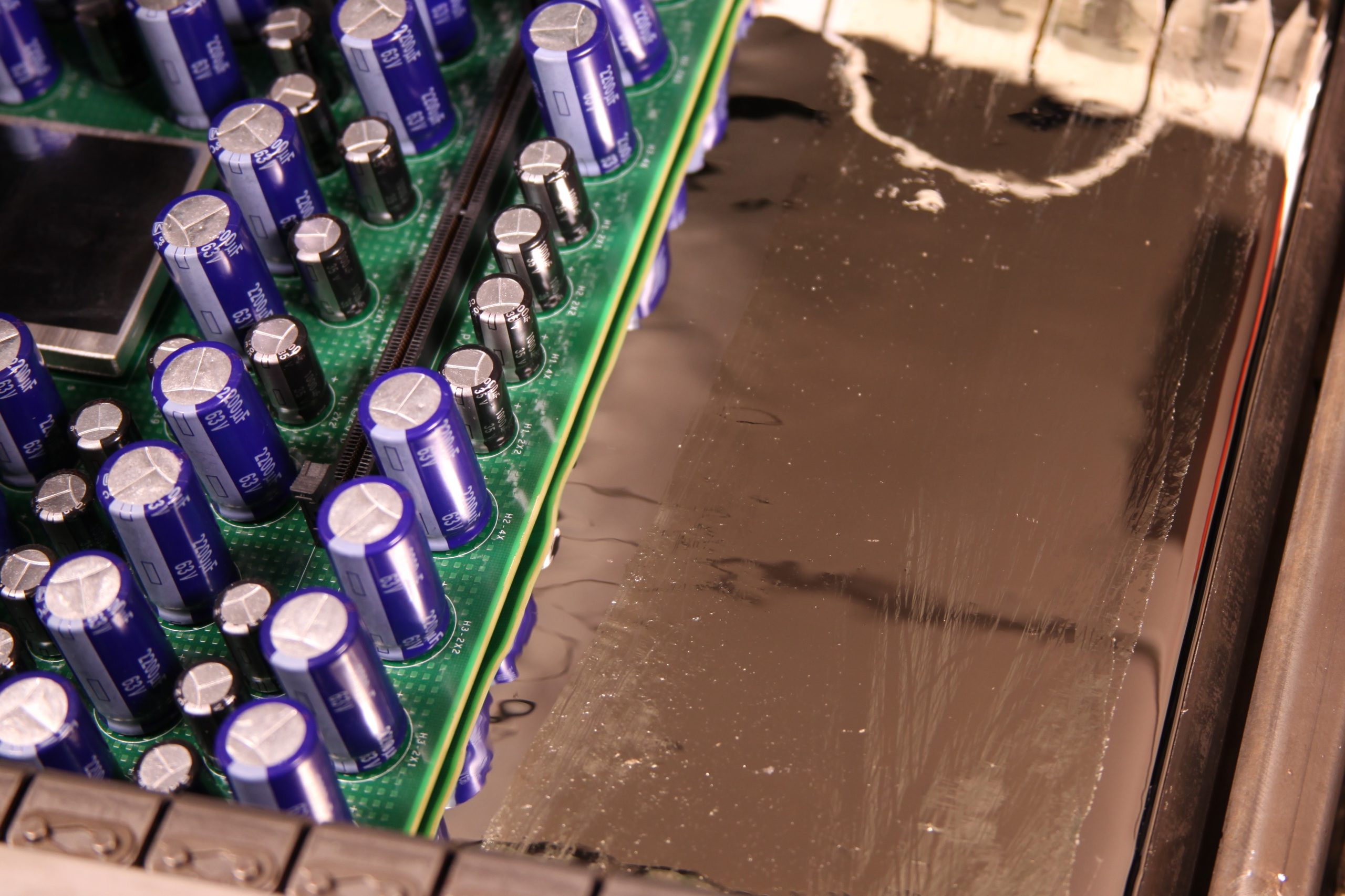

ITW EAE is releasing a new feature for the Electrovert Wave Soldering machines that provides automatic adjustment of the laminar wave flow to match the board velocity. To fully optimize the flow dynamics of the laminar wave, the velocity of the PCB needs to equal the flow of the solder over the weir of the exit wing. When the wave flow is fully optimized, the PCB ‘peels’ away from the solder which minimizes the opportunity for bridging defects to occur.

“Electrovert’s Auto Exit Wing provides highly repeatable, precisely controlled exit wing adjustment that has been proven to deliver up to a 70% reduction in bridging defects and improved topside hole fill,” said Greg Calvo, ITW EAE Wave Soldering Business Manager. “Adjustments are made on-the-fly, eliminating the need for skilled labor to adjust the exit wing manually during product changeover.”

The Auto Exit Wing is activated by a recipe-controlled set-point to ensure optimal wave dynamics for every PCB type and application. Electrovert has built a high level of control and rapid change capability within the wave soldering process which provides great flexibility for lot-size-of-one capability in high-mix soldering applications. The system captures all data required for MES integration.

The Auto Exit Wing feature is fully compatible with all Electrovert UltraFill 4.0 and DwellMax 4.0 nozzles in both Air and N2 Tunnel environments and is field upgradeable.

Electrovert is a brand of ITW EAE, a division of Illinois Tools Works, Inc. They are the largest manufacturer of wave soldering and cleaning equipment for the electronics industry.

ITW EAE brings together world-leading brands of electronics assembly equipment including MPM, Camalot, Electrovert, Vitronics Soltec, and Despatch. For more information visit www.itweae.com.