The anticipation for electronica, the most important electronics industry meeting place, is also growing at GÖPEL electronic GmbH. The expert for JTAG/Boundary Scan and inspection solutions will again be presenting numerous new solutions for the test field and the production of assembled PCBs at Stand 351 in Hall A3.

The stand-alone programmer FlashFOX focuses on the programming of electronic assemblies, significantly reduces production costs and programming times and can be integrated into ATE systems in a space-saving way. Above all, however, it consistently closes the gap in the embedded programming product portfolio due to its compatibility with existing solutions from GOEPEL electronic.

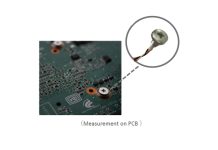

The technology called “Embedded In-System Programming (ISP)” combines different access methods to safely program microcontrollers, flash components and PLD/FPGA devices in parallel and also in critical environments.

The range of multifunctional SCANFLEX II controllers is complemented by the Boundary Scan Controller SFX II PXIe C4/LX, a PXI Express version with a total of 4 onboard test access ports (TAP).

It can be integrated into any type of PXIe rack and enables the combination of embedded test and in-system programming procedures with other test instruments on a common platform. This can significantly improve test coverage in production or prototype testing, for example. On the software side, plug-ins are available for all leading host systems.

The new Boundary Scan controller PicoTAP ATE is a special low-cost boundary scan controller with a USB2.0 interface, a test access port (TAP) and GPIO channels. It is particularly suitable for integration into flying probers and complements the product portfolio of Embedded JTAG Solutions in the lower performance range. The PicoTAP ATE supports all access technologies such as Boundary Scan, ChipVORX and VarioTAP.

In the field of inspection solutions, the AOI system software PILOT AOI Version 7 offers a veritable fireworks show of new functions: fully automatic program generation within minutes with the award-winning MagicClick function and the creation of customised workflows make working with the AOI software even more of a breeze, even for prototypes and pre-production.

Newly created inspection programs can be optimally adapted to production processes by extracting parameters and tolerances from previous production data.

As a recognised expert for flexible and innovative THT inspection systems, GOEPEL electronic repeatedly presents a world first in this field: In the THT Line · 3D, double-sided, parallel inspection of one device is now also possible using dual 3D AOI modules for the top and bottom side of the assembly at the same time.

The new 3D camera module in the AOI system Vario Line · 3D enables increased defect detection, even fewer false defects and thus the saving of valuable resources. This is made possible by excellent optical quality in terms of projection and image capture as well as by intelligent software modules that can dynamically adjust the projection parameters.

To support the operating personnel at the verification station, GOEPEL electronic relies on artificial intelligence. The AI Advisor checks the decision of the classification staff using AI and now also supports the evaluation of X-ray error images.

The latest version 4.3 of the PILOT AXI software for creating inspection programs in the X Line · 3D is now multi-monitor capable. Contents can be freely arranged on several screens. This helps to always have the most important setting parameters in view.

GÖPEL electronic develops and manufactures innovative electrical and optical measuring and testing technology as well as test and inspection systems for electronic components, assembled printed circuit boards as well as industrial electronics and automotive electronic systems. GOEPEL electronic is divided into four business units:

- Automotive Test Solutions

- Embedded JTAG Solutions

- Industrial Function Test

- Inspection Solutions AOI-AXI-SPI-IVS

Further information: www.goepel.com