Koh Young Technology, the industry-leader in True 3D measurement-based inspection solutions and the premier sponsor of SMTA International, will be presenting whitepapers and delivering live demonstrations of its award-winning inspection and measurement solutions in Booth 925 at the Minneapolis Convention Center in Minnesota on 02-03 November. The following is just a glimpse of what Koh Young will have in store for our visitors:

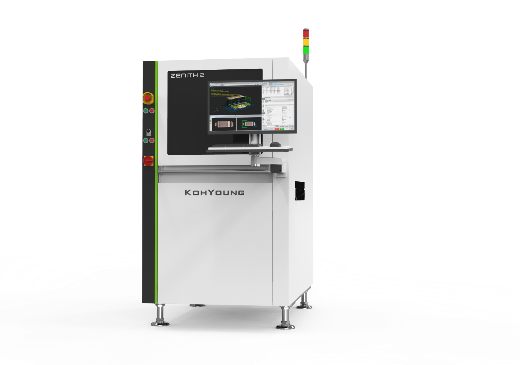

Automated Optical Inspection (AOI)

The Zenith 2 AOI delivers industry-leading inspection performance with True 3D measurement-based technology. In the 2D inspection world, false calls and escapes are unavoidable. To solve this problem, we took a different approach. We based our solution on full 3D measurement technology. We did not start with antiquated 2D technology and its inherent shortcomings. We did not simply add some 3D tech to a legacy 2D system. At Koh Young, our AOI systems measure in True 3D from the start. We find the component body based on true 3D profilometric information. Using this approach, we deliver trustworthy inspection results, regardless of substrate color, board warpage, or component variations. When our 3D measurement data meets our AI engines, we can deliver even more benefits to manufacturers.

Koh Young highlighting Award-winning True3D™ Inspection Solutions at SMTA International 02-03 November 2022

Dispense Process Inspection (DPI)

The award-winning Neptune C+ is the industry’s first 3D optical measurement solution for transparent material inspection. Using Koh Young LIFT technology (Laser Interferometry for Fluid Tomography), the Neptune delivers non-destructive 3D inspection to precisely measure and inspect fluids – wet or dry. With its Machine-Learning algorithm, the Neptune accurately measures materials for coverage, thickness, and consistency with a user-defined threshold setting. It also identifies bubbles, cracks, and other defects in coating. It also measures underfill, epoxy, bonding, glue, potting, flux, and more to deliver an exact measurement of transparent materials.

Koh Young highlighting Award-winning True3D™ Inspection Solutions at SMTA International 02-03 November 2022

Process Control

AI-powered KSMART solutions help automate process control, while focusing on data management, analysis, and optimization. It collects data from across the factory for defect detection, real-time optimization, enhanced decisions, and traceability to improve production, increase quality, and lower costs by eliminating variances, false calls, and escapes. In short, the award-winning KSMART software suite seamlessly turns data into insight to help manufacturers improve the process.

Process Optimization

The Koh Young Process Optimizer (KPO) solution is an AI-based automatic print process optimizer. This system improves the printer offset, as well as critical printer parameters like squeegee speed, print pressure, and separation speed. KPO performs an automated DOE to determine the optimum printing parameters for the best print quality. As a result, manufacturers can optimize the print process, without the need for a dedicated print process expert. Furthermore, KPO monitors and perfects parameters in real-time to guarantee quality despite environmental changes.

Manufacturing Excellence

The partnerships at Koh Young go beyond combining our SPI and AOI machines with printers and mounters from other industry leaders. The MFX5 Smart Factory & Automation session beginning at 1:30pm CST includes a collaboration whitepaper between Koh Young America, AEGIS Software, and the IPC-2581 (DPMX) Consortium. During the session, Ivan Aduna, Global MES Manager at Koh Young will present how to securely exchange data between design and manufacturing using the Digital Product Model Exchange (IPC-2581 DPMX) and Connected Factory Exchange (IPC-2591 CFX) standards.

Koh Young highlighting Award-winning True3D™ Inspection Solutions at SMTA International 02-03 November 2022

To learn more about how our solutions boost your quality, visit us at the SMTA International in booth 925. You can register to attend the in-person conference and exposition at https://smta.org/mpage/smtai-registration. If you cannot

attend the panel, but still want to learn more about smart manufacturing and our best-in-class portfolio of True 3D solutions, vis our site at www.kohyoungamerica.com.

For more relevant content about inspection from Koh Young America:

- “SMT Inspection: Today, Tomorrow, and Beyond”, a downloadable eBook and reference guide: https://iconnect007.com/my-i-connect007/books/inspection/

- Converting Process Data into Intelligence, a 12-part micro series: https://iconnect007.com/my-i-connect007/webinars/processdata

About Koh Young Technology, Inc.

Established 20 years ago in 2002, Koh Young pioneered the market by launching the first 3D Solder Paste Inspection (SPI) system using a patented dual-projection Moiré technology. Since then, it has become the global leader in 3D measurement-based SPI and Automated Optical Inspection (AOI) equipment for the electronics industry. Based on its True3D™ measurement-based inspection technology, Koh Young has developed innovative inspection solutions for challenges with machined parts, press-fit and through-hole pins, conformal coatings, dispensed materials, and semiconductor packages. Through its constant innovation, Koh Young has secured over 3,500 global customers, and maintains the dominant global market share in the SPI and AOI markets with over 20,000 machine installations. By adopting a user-centric R&D focus, it continues to use its core competencies to develop innovative solutions for new and existing markets. Its activities stem from the corporate headquarters in Korea to its global sales and support offices in Europe, Asia, and the Americas. These local offices ensure it stays close to the market, and more importantly, its growing customer base. Learn why so many electronics manufacturers trust Koh Young for reliable inspection for a smart factory at www.kohyoungamerica.com.

For More Information

Brent A Fischthal, Senior Marketing Manager, Koh Young America Brent.Fischthal@kohyoung.com

Koh Young America, 1950 Evergreen Blvd., Ste 200, Duluth, GA 30096 www.kohyoungamerica.com