PBT Works s.r.o., a leading manufacturer of cleaning technology for electronic assemblies and tooling, is pleased to announce that Vladimír Sítko, Founder, Mentor & Co-Owner, will present during the 4th Space Passive Component Days scheduled to take place Friday, Oct. 14, 2022 in The Netherlands. Sítko will present “Details are important. How can the designer help to make cleaning assemblies easy?”

Reliability is the primary concern of electronic assemblies in many applications today. Demands on lifetime and ability to work in a harsh environment require removing flux residues and other pollution from the surface in most such special assemblies.

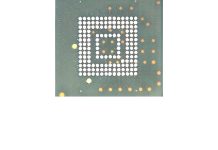

PBT Works has more than 30 years of experience in building cleaning machines and optimizing the cleaning process for electronic assemblies. The team has seen plenty of difficult-to-clean assemblies during this period. Only tiny, almost “invisible” details of the design caused fundamental challenges in removing flux residues. Especially, bottom terminated components of small outlines need to apply special design rules, which may not be included in standard design libraries of CADs. With regard to cleaning, PBT Works considers even simple chips (resistors, capacitors and other passive components) as bottom terminated as well.

The details mentioned in the presentation are not included in any standards simply because there is no standard for such situations. Most design standards come from the era before implementing bottom terminated components. Also, they count on NO- clean processes.

However, the information included in this presentation is based on primary international standards for PCB assembly, optical and electrical inspection criteria, and standardized electrochemical tests of assembly cleanliness.

PBT Works s.r.o. was founded by Vladimir Sítko, former CEO and now Mentor & Co-Owner. Today, his son Robert Sítko is the company’s CEO & Co-Owner. PBT Works has more than 80 employees and is considered one of the world’s top manufacturers of cleaning machines for electronic assembly and tooling.

PBT Works is EN ISO 9001 and EN ISO 14001 certified. For more information, visit www.pbt-works.com.