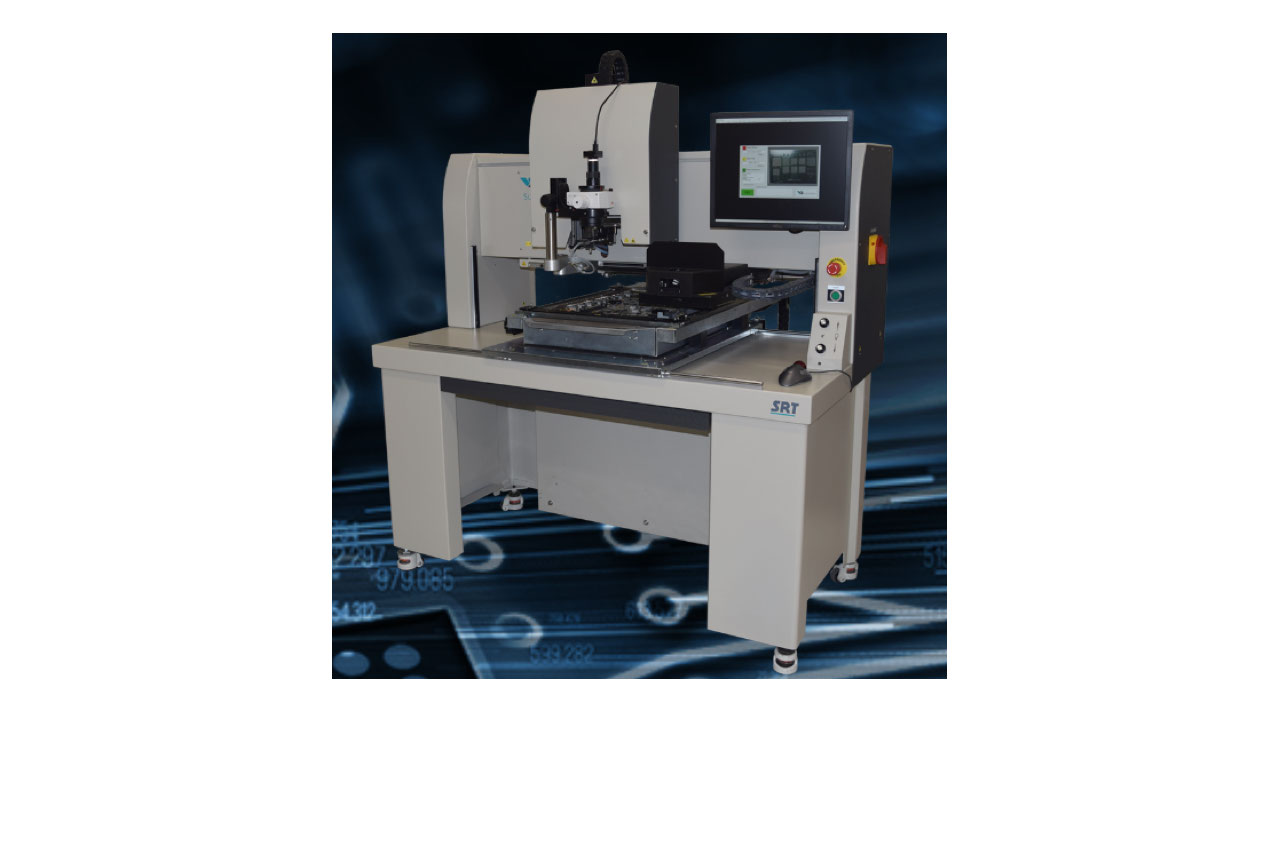

VJ Electronix, Inc., the leader in rework technologies and global provider of advanced X-ray inspection and component counting systems, is pleased to introduce the new Component Auto Align option for its Summit 2200i rework system. The system can now be upgraded via software or purchased new with the option for Component Auto Align.

The new Auto Align feature allows for the alignment of components, including components larger than 100mm, with no operator intervention. The software recognizes the corners of the component and site using fiducials, and then pick locations (centerpoint) are determined automatically.

The Summit 2200i is a high precision, automatic system for small to large SMD assemblies that is capable of handling boards up to 22″x30” and components as small as 01005. The system utilizes efficient convection heating and closed-loop temp control to mimic thoughtfully designed oven profiles.

The system’s easy-to-use 1-2-3-GO graphical user interface and flexible SierraMate rework software minimize operator intervention while maintaining tight process control of all critical parameters and provides product traceability, profile analysis and sharing of profiles between VJE systems.

The independent non-contact site scavenger head safely removes residual solder, eliminates the potential for damage to pads and solder mask, and allows a continuous process without tool change. Operators can complete rework in a single thermal cycle.

For more information about software upgrades, new system purchase or to schedule a demo, visit vjelectronix.com or electronixsales@vjt.com

About VJ Electronix

VJ Electronix, Inc. manufactures production ready, automated Rework and X-ray inspection systems with many advanced capabilities. The company frequently provides custom solutions tailored to satisfy specific application requirements. VJ Electronix is a worldwide leader in X-ray Inspection and Rework equipment.