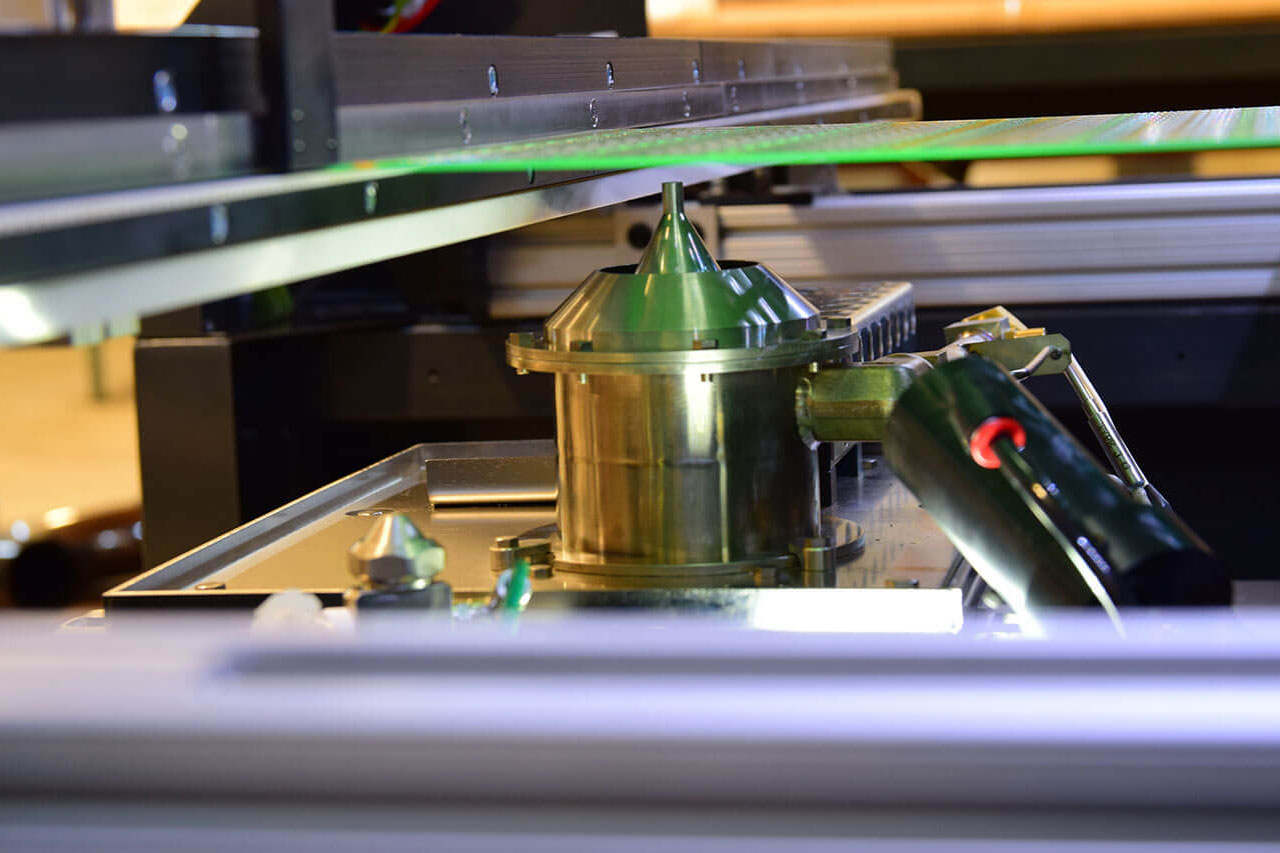

Hentec Industries/RPS Automation, a leading manufacturer of selective soldering, lead tinning and solderability test equipment, announces that due to pent-up demand throughout this past year Hentec/RPS anticipates strong sales activity in 2022 and we foresee robust growth for our entire product line of soldering systems. Our Vector and Valence selective soldering systems feature ease of operation programming software our customers describe as simplistic elegance in operation. The newest addition to our product lineup, the Valence selective soldering system utilizes an electromagnetic solder pump to provide our customers with greater efficiency, better process repeatability and enhanced quality.

The continued need for gold removal, component re-conditioning, tin mitigation and BGA de-balling has increased demand for our Odyssey robotic hot solder dip machines for high reliability and military applications. Our Pulsar solderability test system utilizes the highly proven dip-and-look test method to determine the solderability of various through-hole and SMT components to ensure quality circuit board assembly. Throughout 2022, Hentec/RPS will continue to provide new product innovations to meet our customers printed circuit board assembly needs.

About Hentec Industries

Hentec Industries/RPS Automation is a manufacturer of automated selective soldering, component lead tinning, and solderability test equipment for electronics and electronic component manufacturing, assembly, and distribution. Hentec/RPS has been advancing automated soldering and lead finishing technology for defense, aerospace, automotive, contract manufacturers and micro-electronics component manufacturers since the early 90’s. All Hentec/RPS products are designed and manufactured in Newman Lake, Washington.

For more information, please visit us at rpsautomation.com