To increase electronics reliability in the harshest of environments, the global electro-chemicals manufacturer, Electrolube, will launch its most exciting conformal coating and thermal management innovations yet at this year’s Productronica (Messe Munich, November 16-19). Protective solutions taking centre stage at the show will be a highly thermally conductive thermal gap filler suitable for a wide range of applications including EV’s, batteries and chargers to name but a few, and a game changing new two-part, bio-based conformal coating that is completely unique to the industry; an absolute game-changer. Electrolube will showcase their newest innovations on the Macdermid Alpha booth 466 in Hall A4.

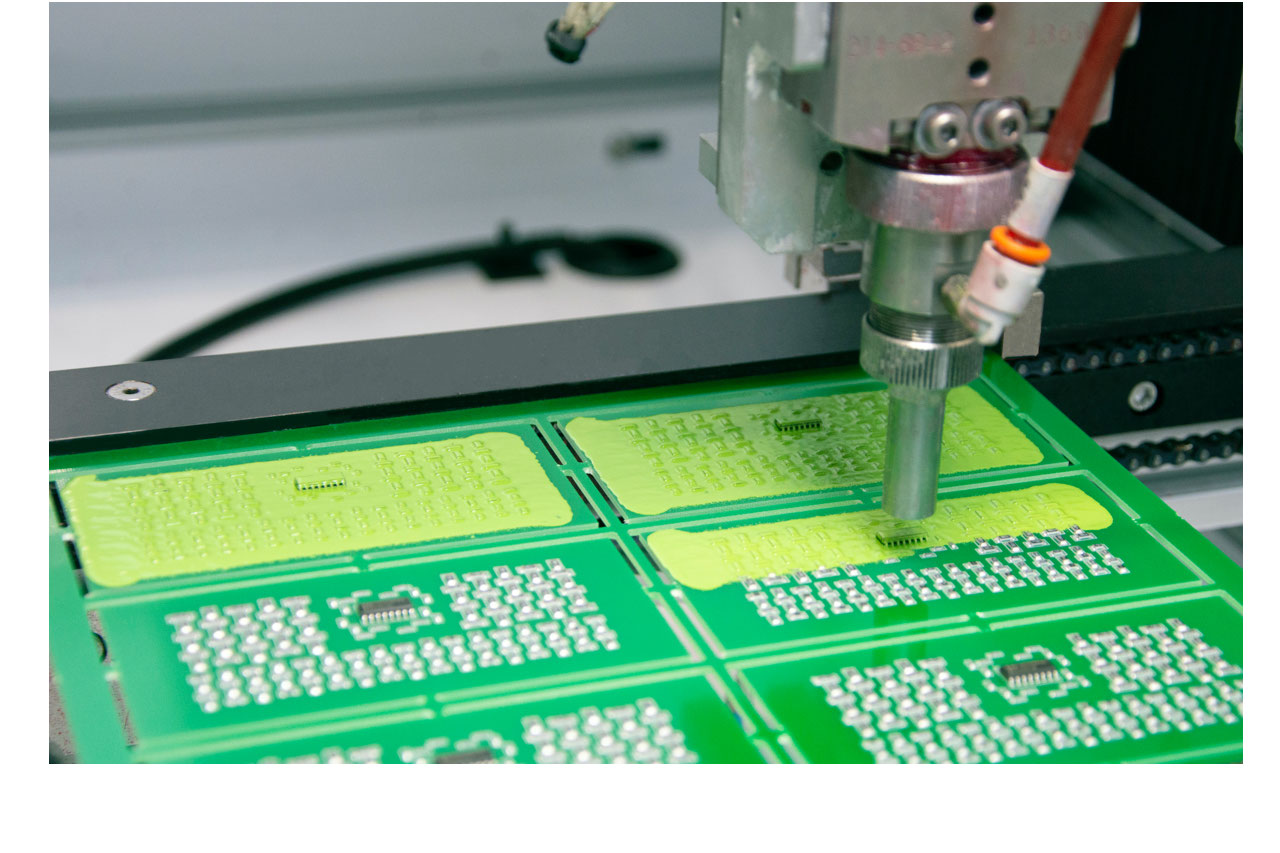

One of the company’s biggest breakthrough products is set to transform the future of coatings across the industry. Yet again, Electrolube has embraced industry trends and produced a first-to-market conformal coating with exceptional properties that can de deployed wherever a coating is needed and is ideal for automotive and EV applications. More about Electrolube’s versatile new coating will be announced pre-launch, and those interested can learn more from Electrolube’s digital marketing platforms.

Electrolube has several decades of expertise in protecting automotive electronic assemblies that are subject to extremes of temperature, chemical attack from fuels, lubricants and salt mist atmospheres, as well as high levels of mechanical shock and vibration. Electrolube’s high level protection solutions ensure consistent operation of critical automotive control and safety-related components. Extensive research in this area has, as always, been a cross-collaboration between Electrolube’s three international R&D teams in the UK, China and India. Successive innovations have become products of choice among the world’s leading automotive electronics manufacturers.

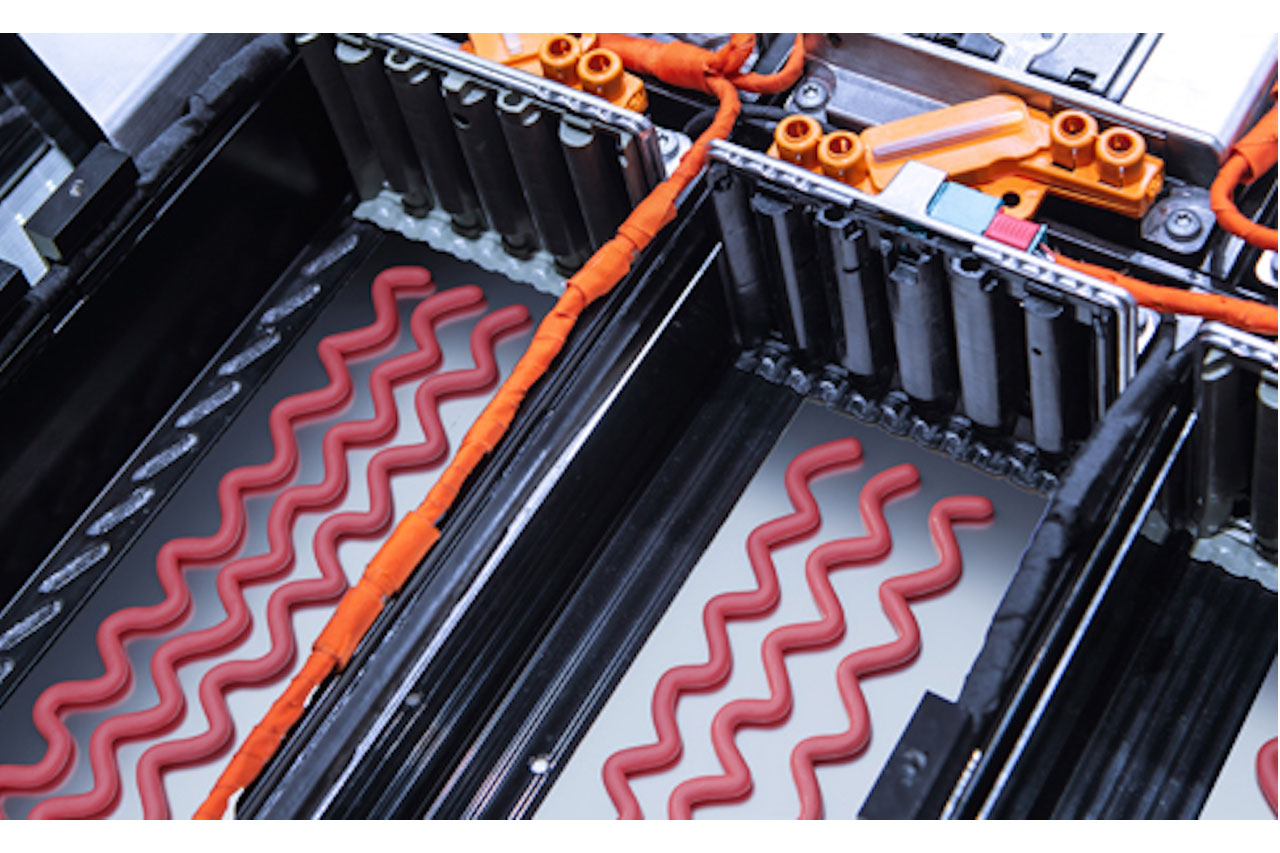

Pushing the boundaries of thermal management even further, Electrolube will debut the new GF600 thermal gap filler. GF600 is a two part, liquid silicone based gap filler, which provides excellent thermal performance and can be cured at room temperature or accelerated with heat. After curing, GF600 forms a low modulus elastomer, preventing the ‘pump-out phenomenon’. The low viscosity gap filler is easy to dispense and is soft and compliant for low stress applications. With extremely high thermal conductivity of 6.0 W/m.K and a wide operating temperature range from -50 to 200°C, the flame retardant GF600 is ideally suited to filling gaps and air voids, even in the most delicate of devices with minimal stress. Designed to provide greater stability than traditional thermal interface materials, the GF600 flows into all the voids and small gaps that are present at an interface between two substrates, allowing for minimal bond line thickness and minimal thermal resistance at the interface. GF600 also remains more stable over many thermal cycles.

Performance, safety, lifetime and reliability require the most effective protection materials available. Electrolube’s portfolio of conformal coatings, thermal management products and encapsulation resins for automotive, Electric Vehicles and EV battery applications include the thermally conductive epoxy potting compounds, conformal coatings and thermal management materials

Visitors to Productronica are invited to meet the Electrolube team in Hall A4 of the Messe München, Booth 466. During the course of the show, Electrolube will be showing visitors the capabilities of their ground breaking new conformal coating and brand new gap filler, and will be happy to talk to visitors about their process and application requirements, and advise on solutions that really make a difference.

For further information, please visit electrolube.com