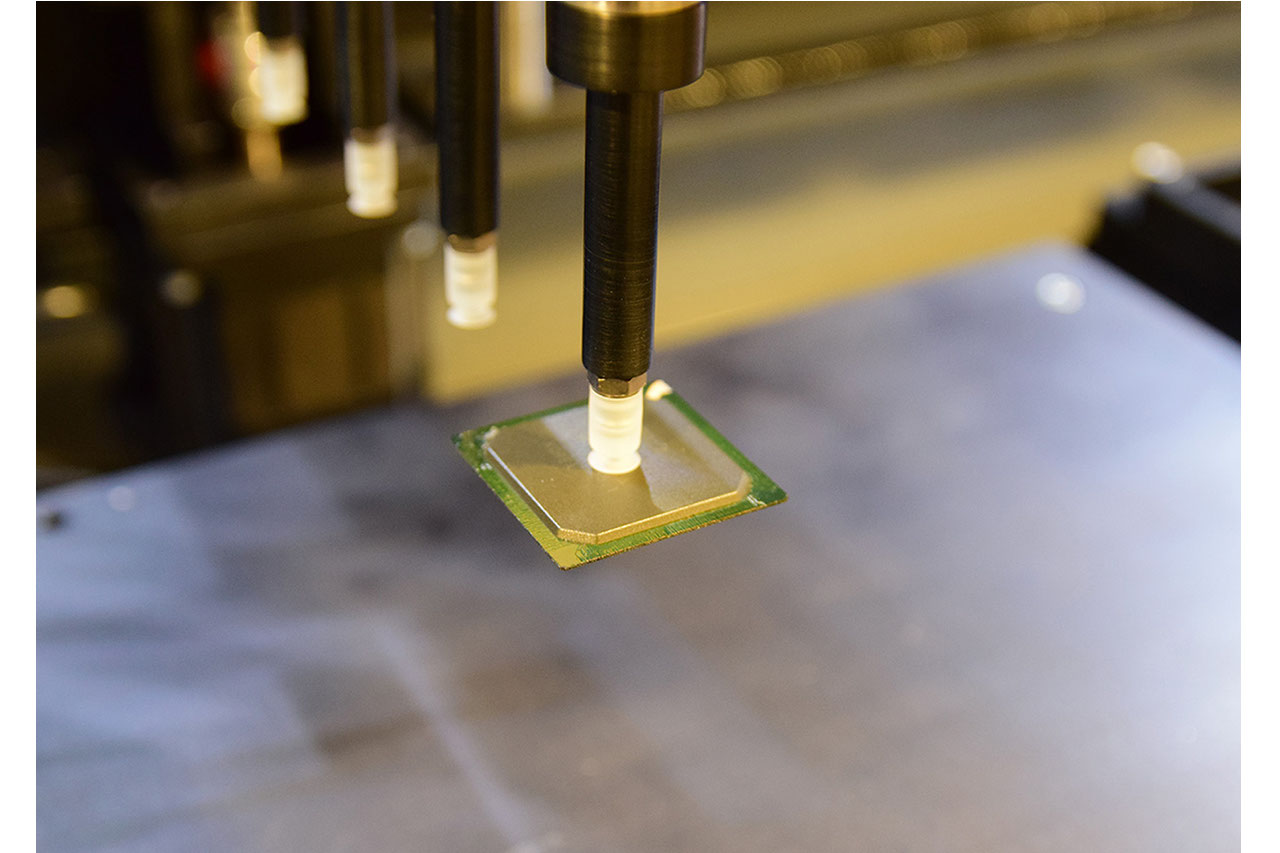

Hentec Industries/RPS Automation is pleased to announce that the Circuit Technology Center has issued a purchase order for two additional Hentec/RPS Odyssey 1325 robotic hot solder dip machines. The Odyssey 1325 is a MIL spec complaint high-volume, high-mix component lead tinning machine equipped with auto load/unload and is capable of processing dual solder alloys. Designed to tin component leads for re-conditioning, gold removal and re-tinning applications, including high reliability and military applications including DIP, SIP, QFP, BGA, axial and radial components as well as BGA de-balling. The Odyssey 1325 complies with all applicable GEIA-STD-006, MIL-PRF-38535, MIL-PRF-38524E and ANSI-J-STD-002 standards.

“This purchase will double the existing capacity of Circuit Technology Center’s component level modification services department to meet the increasing demand from the defense and high reliability customer base that requires component level modification and alteration for tin whisker mitigation, gold mitigation and lead tinning re-conditioning applications”, said Andy Price, Sales Manager at Circuit Technology Center. “This Hentec/RPS state-of-the-art equipment is also used for automated, touch-less BGA component de-balling, required as part of converting BGA’s with lead-free solder to tin-lead solder.”

“For nearly 40 years, leading defense and aerospace companies have relied on Circuit Technology Center as the world leader in circuit board level modification and damage repair services” continued Andy Price. “We are thrilled to announce this capacity expansion offering our defense and high reliability customers component level modification and alternation services with the same level of exceptional quality and service that they have come to expect from our company and our lead tinning equipment supply partner of choice.”

For more information, please visit: circuitrework.com and rpsautomation.com