BOFA, a market leader in portable fume and particulate extraction technology, is unlocking the value of data for the laser industry through its new iQ2 platform, as featured on the company’s best-in-class AD Oracle system.

The iQ2 operating system sets a new benchmark in data collection, condition monitoring and remote diagnostics – enabling manufacturers to analyse 12 months of onboard performance data to maximise filter life and plan exchange cycles more accurately than ever before.

Haydn Knight, Sales and Marketing Director at BOFA, said: “This extended data capability is particularly valuable for high volume laser settings because with increasing line speeds, filter capacity is now best measured through units of product rather than units of time.

“The volume and type of data provided will enable operators to accurately predict their filter exchange cycle in step with maintenance routines and thereby avoid the risk of costly unplanned downtime.”

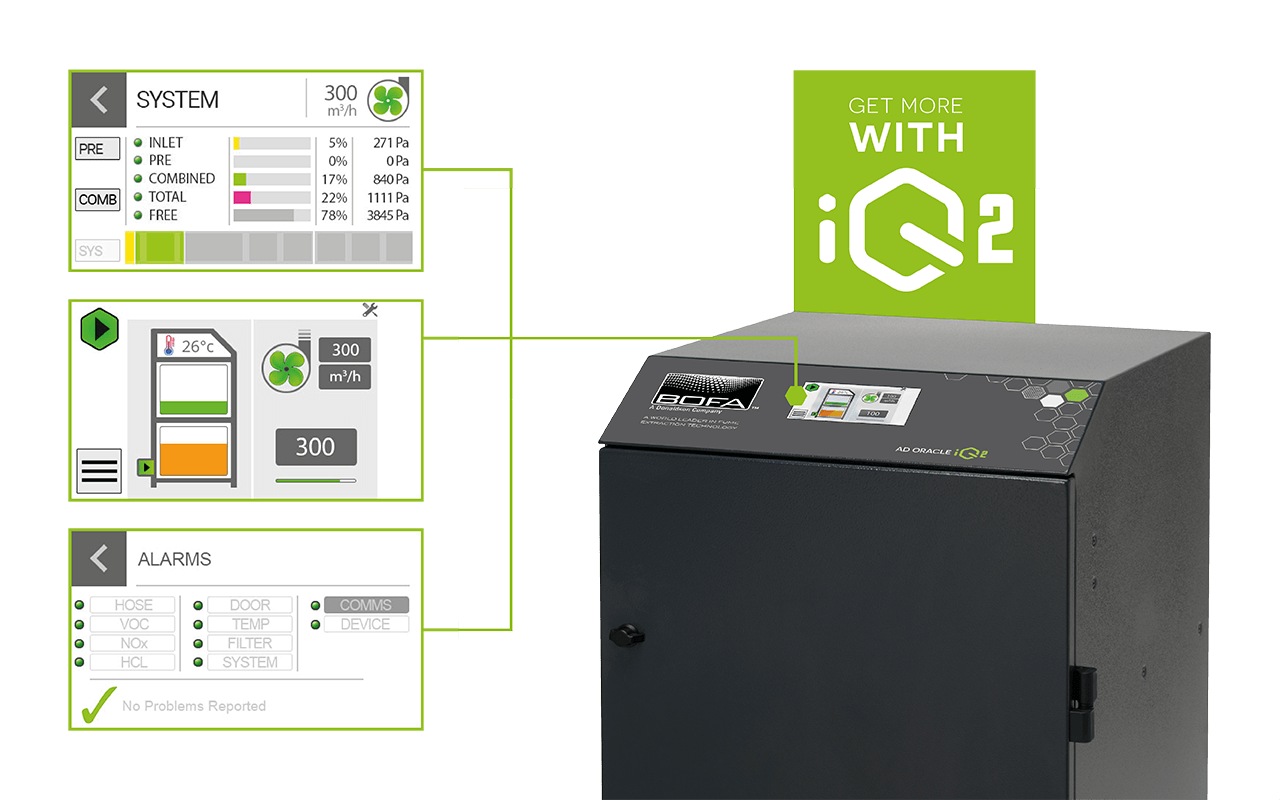

In addition to extended data sets, BOFA’s iQ2 supports intuitive visual read-outs, presenting overall extraction performance and the status of individual system elements in real-time via a colour touchscreen interface.

The information is displayed using internationally recognised icons and multi-language options, making it easy for manufacturers to quickly review filter status, system temperature, percentage motor running and operating efficiency. This can help head-off potential issues before they impact on production.

Over and above this, detailed analysis of extraction performance is captured routinely in system ‘snapshots’ stored onboard to provide ongoing value-adding analytics that can contribute to improved productivity.

Said Haydn Knight: “iQ2 is also future-proofed by enabling access to future BOFA features through easy-to-install software upgrades, a capability that will become increasingly important for system integration as industry embraces a new era of automation.”