Zollner Elektronik AG has opted for two 3D X-ray systems of the latest generation iX7059 PCB Inspection XL from Viscom AG. Both systems supersede outdated inspection systems for assemblies in the industrial electronics sector.

“Our challenge involved finding an adequate successor for our previous X-ray inspection system, which would cover the functionalities of existing systems – already highly sophisticated – and would also be able to meet future requirements of our customers. Issues such as printed circuit boards with excess length and high weight also need to be considered at the same time as increasing miniaturization. Another wish was to be able to inspect assemblies inline – and here decreasing cycle times are coupled with increasing quality requirements. Since the iX7059 PCB Inspection XL from Viscom meets these requirements, we decided to purchase two systems,” explains Andreas Koller, responsible for Global Engineering Testing Technology at Zollner Elektronik AG.

With its iX7059 product line, Viscom is setting a new standard for fast, high-precision inline X-ray inspection. In particular, the 3D X-ray system iX7059 PCB Inspection XL is able to inspect very long PCBs in lengths up to 1600 mm. The same also applies to particularly heavy test specimens of up to 15 kg, such as modules that have already been assembled or are transported on workpiece carriers.

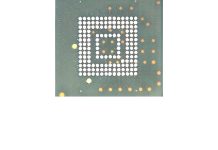

In addition to traditional SMD inspection, the iX7059 PCB Inspection XL also provides high-precision, reliable inspection of assemblies for soldering defects such as head-in-pillow and pores in BGA and LGA components and voids in surface soldering, fill levels on THT solder joints and measurement of press fits. This makes the system ideally suitable for LED-processing electronics manufacturing – especially owing to the possible inspection of long LED strips – but also for the inspection of large and heavy server boards as well as semiconductor and 5G electronics. For industries where the functionality of the end product is subject to high safety standards – such as in safety engineering for automotive applications, but also in server technology and high-end telecommunications – high-precision inspections are also necessary, for which the iX7059 PCB Inspection XL is an attractive alternative to existing systems.

“We intend to use both inspection systems as a test island,” Koller continues. In inline production, the iX7059 PCB Inspection XL supersede systems that have been used for many years and no longer meet the new requirements. During the inspection process, the board is checked in particular for correct and complete assembly, defect-free solder joints and the presence of voids.