Nordson Electronics Solutions, a global leader in electronics manufacturing technologies, announces the new ASYMTEK Forte™ MAX fluid dispensing system with high accuracy, dual-valve jetting in two modes, and patented, real-time correction to accommodate skewed parts. Designed for high-volume electronics manufacturing, Forte MAX improves throughput for printed circuit board and flex circuit assembly, MEMs, and electro-mechanical assembly when dispensing sealants, encapsulants, underfills, and precise coating.

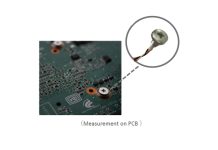

The Forte MAX system dispenses from two identical or two different valves using a single set of hardware. In one configuration, two high-frequency IntelliJet® Jetting Systems dispense fluid simultaneously for applications with multi-up, panelized, or patterned parts with consistent spacing. In a second configuration, two different fluids are dispensed on the same part from two different valves, such as for dam-and-fill encapsulation and in high-mix production environments. A unique skew adjustment comes with the dual-valve system so that production is not slowed by shifted parts and varied component heights. The patented real-time correction automatically adjusts for skewed parts and component height variation in the x, y, and z-axes (Nordson US Patents 9,707,584; 10,150,131; 10,737,286 and other patents pending).

One customer has seen a 100% increase in throughput with the Forte MAX system after upgrading from the popular Spectrum II with two original DispenseJet® DJ-9500 valves. During the underfilling operation, several factors contribute to the improvement: the motion control system checks fiducials quicker and moves the jets faster. The real-time skew correction increases the number of good parts produced. The IntelliJet systems operate at 500 Hz, versus older jets at 200 Hz, resulting in fluid being deposited more quickly. In addition, setting up the Forte MAX is simpler and more efficient so that changeovers are easier and faster.

The integrated dual-valve service station, closed-loop process controls, and nozzle-cleaning rail reduce operator maintenance, improve productivity, and keep the dispensing process within set limits. The system runs with Canvas® dispensing software, which simplifies programming tasks. Graphical programming lets you scan a workpiece, develop your program on or offline, and simulate the dispensing results on a virtual canvas.