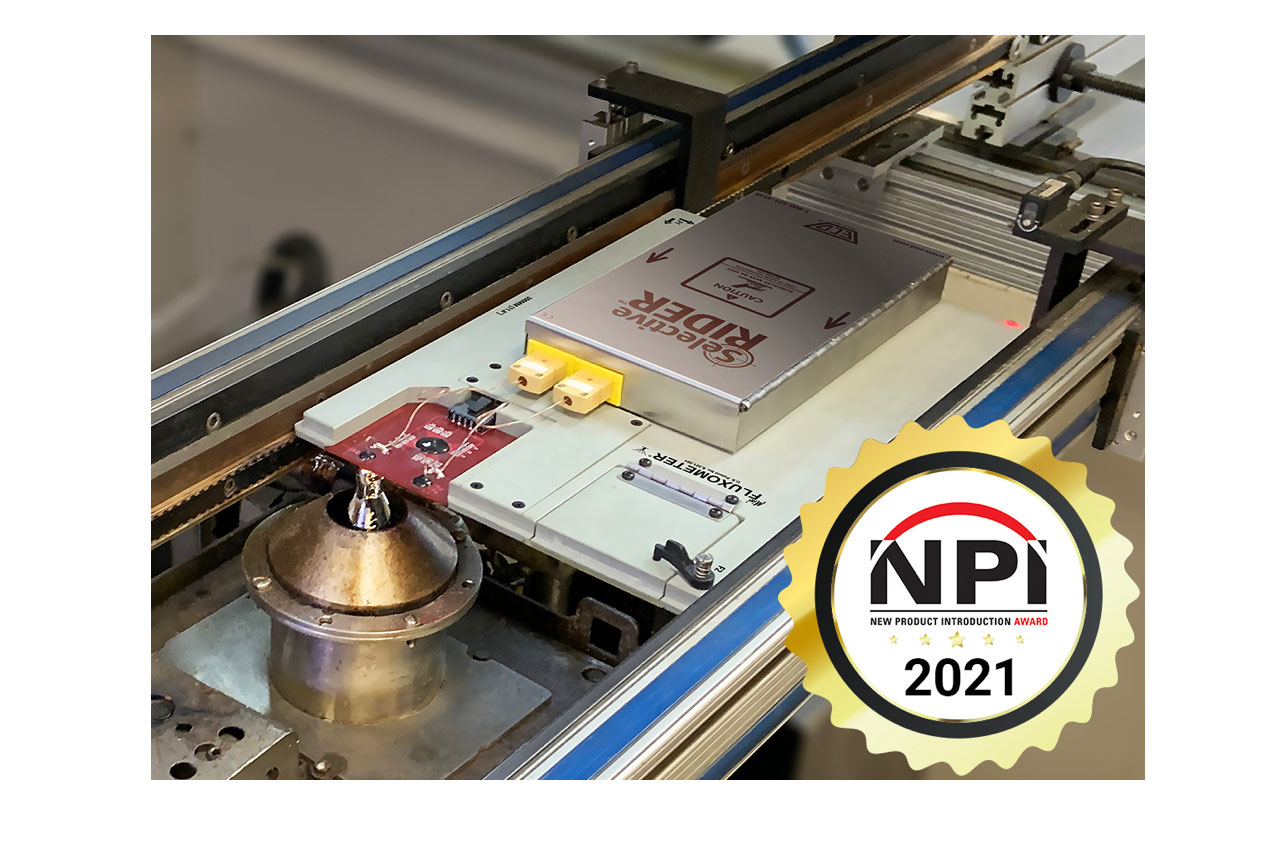

On the heels of its market launch in Q4 2020, ECD’s SelectiveRIDER™ has landed its first industry honor with a Circuits Assembly magazine NPI Award win. Evaluated across challenging criteria including innovation, compatibility with existing technology, cost-effectiveness, design, flexibility, performance and user-friendliness, SelectiveRIDER earned the top score in the ‘Selective Soldering Tools and Accessories’ category.

As adoption of the selective soldering process expands, it is increasingly important to leverage third-party tools to verify equipment accuracy and performance for assurance of ongoing product quality and process control. ECD’s SelectiveRIDER combines the measurement of all three phases of the selective soldering process (fluxing, preheat and soldering) into a single, self-contained and easy-to-use pallet. The system’s unique design enables precise capture of these key parameters in a single pass:

- Flux penetration and positional accuracy

- Maximum preheat temperature, solder temperature and delta T at the point of contact

- Solder fountain height, positional accuracy and diameter

With SelectiveRIDER, powerful MAP software provides data analysis, interpretation and archiving; color-coding of results enables simple go/no-go decision making; and full SPC comes as standard. Meaningful measurement data is presented in an at-a-glance summary view, and out-of-specification measurements are easily identified with red or blue highlights for quick understanding and action.

Adaptable and easy-to-use, SelectiveRIDER is compatible with all brands of selective soldering equipment. To learn more, visit this online resource.