Viscom’s proven S3088 CCI inspection system ensures high-precision conformal coating inspection of printed circuit boards. The system quickly and reliably detects typical defects such as cracks, coating voids, smearing and splashing. Layer thickness and wet coating can also be analyzed. The S3088 CCI now comes standard with an unmatched upper transport clearance of 105 mm, thus providing even more flexibility during final inspection of fully assembled components.

Conformal coating is becoming increasingly important in electronics manufacturing. Coating is applied wherever electronic components need to be protected against damaging environmental influences. This is especially the case for safety-relevant applications. The rapid and continued development in electromobility and autonomous vehicles, as well as the growth of wind energy, have made this production step all the more essential. The insulating effect of conformal coatings responds to the trend toward miniaturization by allowing the distance between conductor paths to be reduced.

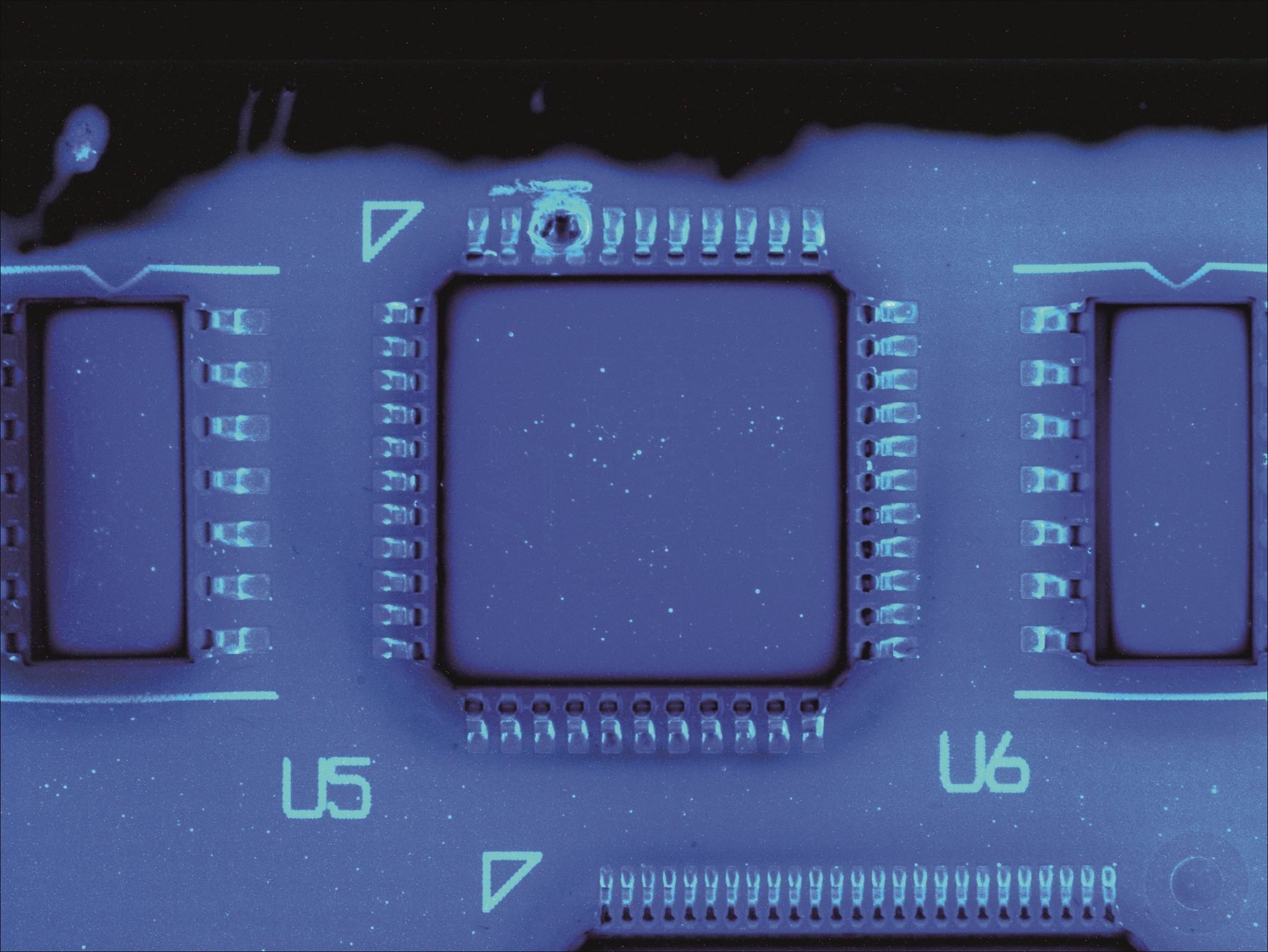

The inspection process uses white light and special UV LEDs which reliably reveal defects in UV-sensitive conformal coating. The S3088 CCI’s flexible inspection algorithms can be rapidly adapted to various conformal coatings. Optimal inspection coverage is ensured by means of one orthogonal camera in combination with four, or optional eight, angled view cameras, which allow for accurate inspection of component sides and gaps between pins. With a maximum orthogonal resolution of up to 15 μm/pixel and an angled view resolution of up to 17.5 μm/pixel, the S3088 CCI inspects all typical defects with 100% reliability — and thanks to the standard four, or optional eight, side views, inspection results are free of shadowing. Special high-powered LEDs are used for the inspection of poorly reflecting coatings, such as conformal coatings which are very thin or coatings which contain silicone. The system also provides layer thickness measurement (3D spot measurement), nanolayer inspection and wet coating inspection. Additional inspection of selected post-reflow criteria, such as OCR and displacement, is also available.

The camera system works with the vVision or EasyPro inspection software, thus offering the same user interface as other AOI systems in the proven S3088 family. Inspection program creation is hence quick and easy. As a result, traceability concepts, special inspections such as reading labels with data matrix code (DMC) and other production-relevant features can be implemented effectively. Moreover the documentation of all process data is guaranteed.

About Viscom

Viscom AG develops, manufactures and sells high-quality inspection systems. The portfolio encompasses the complete bandwidth of optical and X-ray inspections.

Viscom is one of the world’s leading providers of assembly inspection systems for the electronics manufacturing industry. Systems from Viscom can be networked and customized to meet specific customer needs. The company headquarters and manufacturing location is in Hanover, Germany. With a large network of branches, application centers, service support points and representatives, Viscom is represented internationally. Founded in 1984, Viscom has been listed on the Frankfurt Stock Exchange (ISIN: DE0007846867) since 2006. For more information, visit: viscom.com

![1_Viscom_Pictures_System_S3088_CCI[1] copy 1_Viscom_Pictures_System_S3088_CCI[1] copy](https://smttoday.com/wp-content/uploads/2020/11/1_Viscom_Pictures_System_S3088_CCI1-copy.jpg)