Many automotive electronic components have always been classified as safety-critical devices. However recently, with the advent of self-driving vehicles, control over the quality of the sensors used and of their associated electronic and semiconductor elements has become significantly more important. To measure such components reliably and efficiently, Nikon Corporation in Japan has developed a new, high-speed video measuring system that provides unparalleled accuracy, repeatability and reliability in a shop floor or in-line production environment.

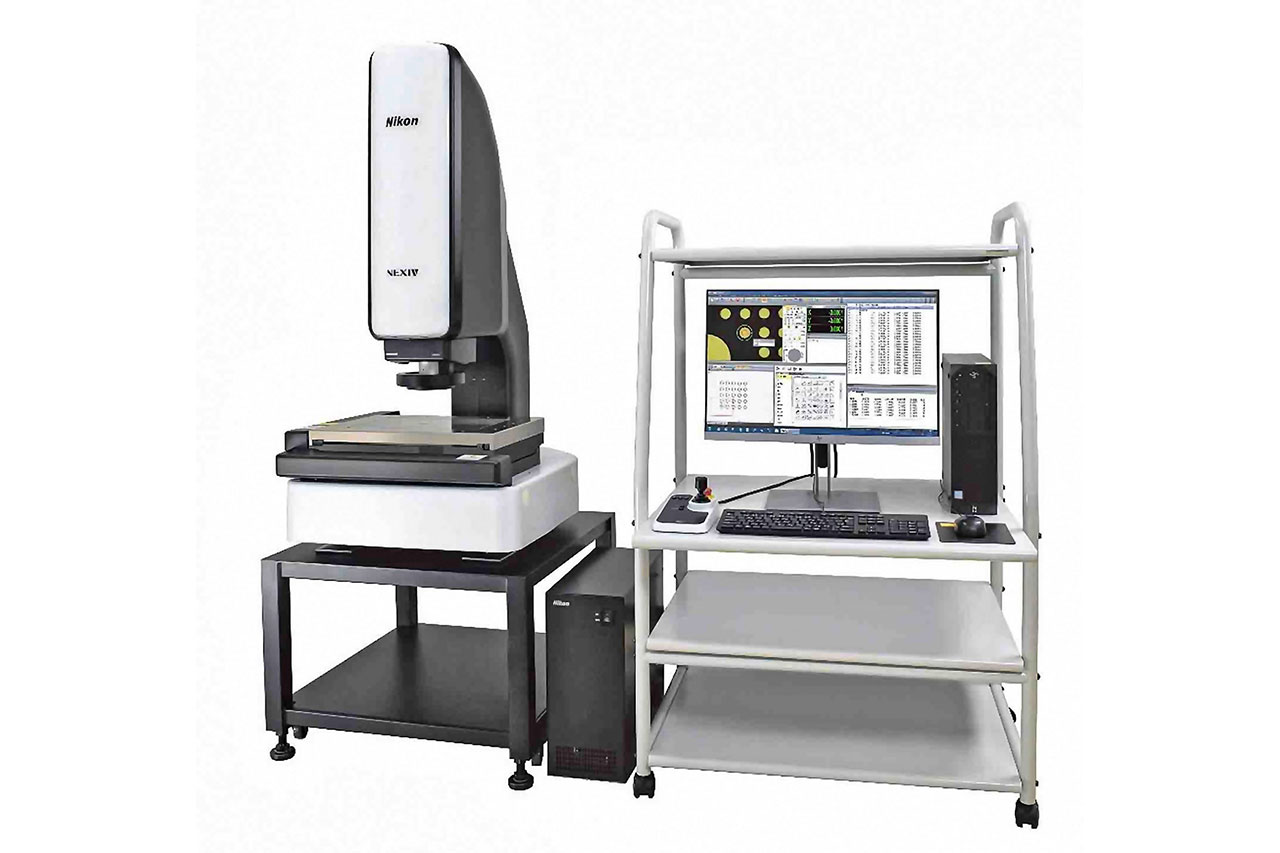

Also known as an optical video measuring system, NEXIV VMZ-S3020 is perfect for automated quality control. It has been designed to meet the needs of companies worldwide manufacturing printed circuit board assemblies (PCBAs) for the automotive sector, for example, as well as other smart, electronically supported components.

The emerging technology of autonomous driving comes alongside the accelerating development of fully electric and hybrid vehicles, which incorporate a far larger number and variety of electronic components than cars with an internal combustion engine. These semiconductor-based devices and circuit boards require effective, reliable, high-speed and accurate inspection.

The NEXIV VMZ-S3020 is suitable for measuring components within its 300 x 200 x 200 mm working volume. Numerous enhancements to the robustness of the unit and its functionality have been made compared with the instrument that it replaces, model VMZ-R3020. Nikon’s proprietary optical measuring, image processing and analysis technologies are employed to detect feature edges at very high speed, capturing accurately and automatically the shape and dimensions of even the most complex and multi-layer PCBAs. Results may be fed back to the production line to ensure that parameters remain within tolerance, providing real-time optimisation of the manufacturing process in a smart factory.

Maintaining the highest measuring precision and consistency using Nikon’s in-house developed, high-resolution linear encoders to feed back the precise position of the stage axes to a control centre, the new NEXIV VMZ- S series can achieve even faster movements and image capture steps by the dedicated CMOS camera. Image transfer and subsequent processing of the data are also quicker. This has made it possible to reduce measurement cycle times to achieve higher throughput, without compromising accuracy or reproducibility.

Nikon has designed top-quality optical systems using its own exceptional “glassware” to deliver the highest quality images and so realise ever more accurate measurement data within the field of view and beyond. Enhancements to the through-the-lens (TTL) laser auto focus, giving repeatability to better than half a micron, have strengthened trust in the system’s ability to measure profiles and transparent components with the highest performance.

Fast laser scanning at 1,000 points/sec can rapidly acquire the cross-sectional shape of a surface and evaluate the relative heights, meeting the measurement needs across a wide variety of samples. Indicating the attention to detail that has been bestowed on the new instrument, even the joystick unit that moves the stage and measurement head has been redesigned to be even easier to use.

A fully featured measurement software environment, NEXIV AutoMeasure, enables high precision, high speed, easy measurement cycles using tools that are close to hand in a user-friendly GUI. For components of simple shape, it has been enhanced with support functions which automate part of the measurement programming processes.

Larger NEXIV versions, VMZ-S4540 with X,Y,Z strokes of 450 x 400 x 200 mm and VMZ-S6555 with strokes of 650 x 550 x 200 mm, are scheduled to be released in 2021 to provide the same benefits when measuring larger objects such as printed circuit boards or critical mechanical parts loaded in batches.