Thermal Profiling and Process Verification Leader Boasts Most Comprehensive Soldering Offer with Debut of Selective Soldering Tool

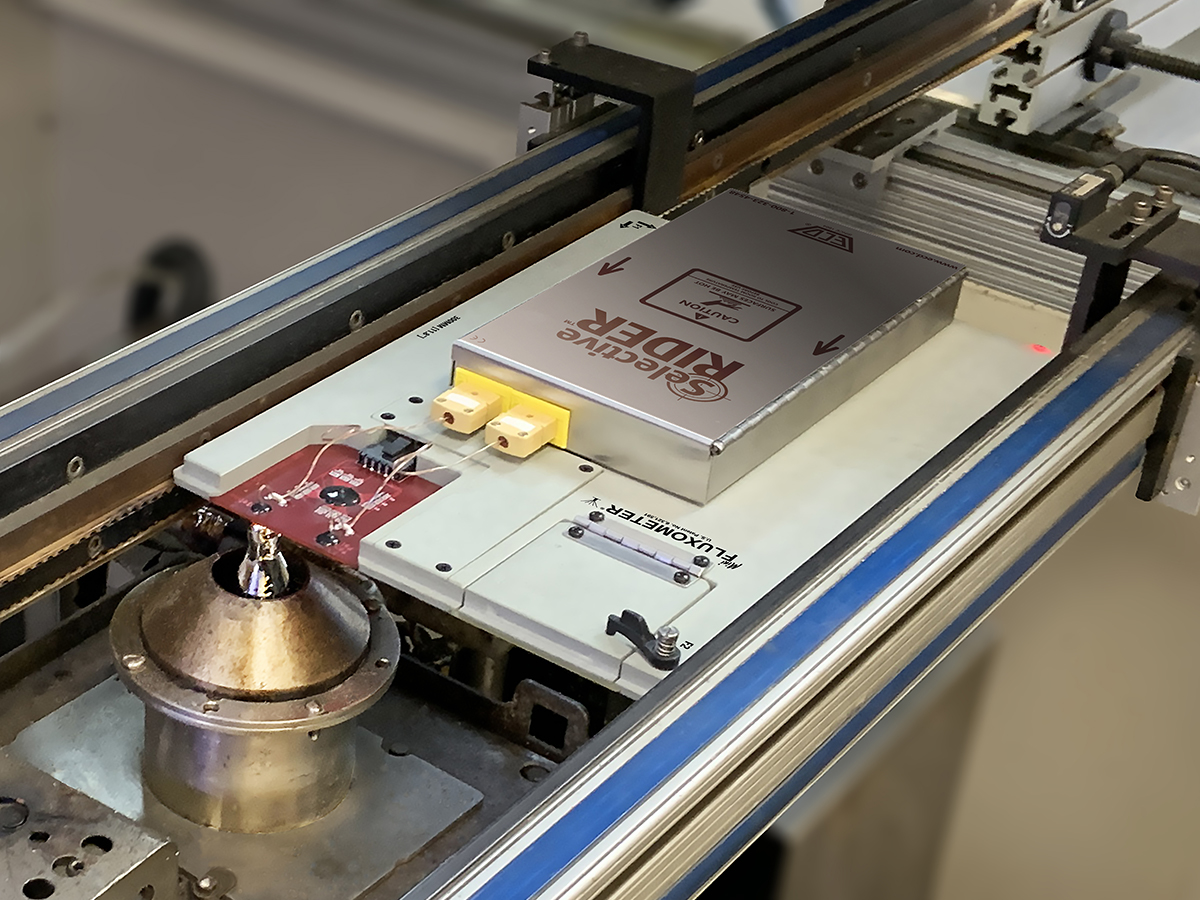

ECD have announced the addition of SelectiveRIDER™ to its portfolio of soldering process measurement pallets, effectively closing the loop to deliver a complete line of automated verification technologies for every machine soldering process: wave, reflow and selective. Like all ECD verification RIDERs, the selective soldering measurement pallet integrates with the SuperM.O.L.E. Gold 2® thermal profiler and ECD’s M.A.P. software for a seamless, optimized solution.

SelectiveRIDER enables thorough validation of the three phases of selective soldering: fluxing, pre-heating and soldering. Each element is precisely measured using a novel pallet design; data logging is achieved with the award-winning SuperM.O.L.E. Gold 2 profiler; and M.A.P. software facilitates data analysis and SPC. The self-contained tool combines precision flux measurement via ECD’s miniFluxometer™ V-gage test coupon, thermal parameter verification and wave metrics including X/Y positioning, Z height, diameter measurements and dwell times.

“SelectiveRIDER provides third-party, independent verification and confirmation of selective soldering process parameters,” says ECD EMEA Operations Director, Mike Hayward. “This is essential to secure system repeatability for high-yield, high-quality product output.”

SelectiveRIDER’s unique feature set includes:

- Thorough flux location and accuracy verification; not just flux absence or presence

- Confirms dispense X/Y positional precision, with indication of any offset

- Identifies blocked or unprimed spray heads

- Verifies deposition (dot) size and captures any under- or over-spray

- Indicates flux penetration success

- Excellent solder fountain measurement accuracy

- Dynamic X/Y sensor measures from target center, and solder fountain diameter

- Fountain height precision confirmed to within 0.5 mm with graduated sensors

- Dwell time accuracy to +/-0.01 seconds

- Thermal parameters

- Accurately measures maximum pre-heat temperature, solder temperature and Delta T during soldering

Simplicity and ease-of-operation are also hallmarks of ECD’s pallet series; SelectiveRIDER is no exception. Using the tool is as simple as loading the recipe, inserting the SuperM.O.L.E. Gold 2 profiler, turning on the profiler to record, securing the SelectiveRIDER cover and running the pallet in the machine. Data downloads are fast and easy and summative data views in M.A.P. software highlights out of specification data with simple color coding.

“With the SuperM.O.L.E. Gold 2 and ECD’s RIDER family, assembly specialists now have full control of the three major machine soldering processes,” concludes Hayward. “SelectiveRIDER is a minimal investment for maximum return in product quality, machine uptime and proof that the soldering operation is in control.”

Learn more by visiting the SelectiveRIDER web resource or registering to attend a November 19th webinar.

Except as otherwise noted, all marks used herewith are trademarks and/or registered trademarks of ECD and/or its affiliates in the US and elsewhere.

About ECD

Founded in 1964, ECD is recognized worldwide for its leadership and expertise in thermal monitoring and analysis technology and, more recently, for its development of intelligent dry storage systems. Based in Milwaukie, Oregon, the company is a pioneer in the design, development, and manufacture of advanced in-transit thermal profiling systems and software used to monitor and analyze process temperatures in various industries including electronics, solar and baking, among others. Well-known for its data-rich software expertise and robust hardware functionality, ECD leads the industry for innovative measurement and safeguarding systems. For more information on ECD and its products, visit ecd.com