Artificial Intelligence (AI) is a buzzword often used with business and industrial technologies. Recently, it has demonstrated promising potential across a variety of industries – from self-driving cars to virtual doctors – all of which, though, have been limited exclusively for people.

AI, however, has far-reaching applications within the manufacturing sector. By combing the right AI technologies, manufacturers can boost efficiency, improve flexibility, and even achieve self-optimizing processes. Printed circuit board assembly is no exception. Complementing the machine communication standards by industry associations, equipment providers like Koh Young are enabling the smart factory by adopting AI to generate “knowledge” from “experience.” We invite you to attend the virtual SMTA International Conference and Exhibition. Join us from 28 Sep-23 Oct 2020 for the On-Demand Conference & Expo and make sure to log in for the Live Virtual Exposition from 28-30 Sep 2020.

During the event, you can learn more about how Koh Young uses its AI and Machine Learning solutions in its Solder Paste Inspection (SPI), Automated Optical Inspection (AOI), DPI (Dispense Process Inspection), and Dispense Process Inspection (DPI) / Conformal Coating Inspection (CCI) systems, as well as its KSMART Software Solution Suite and the Koh Young Process Optimizer (KPO) for printers and mounters. What’s more, Koh Young will unveil new solutions like its KY-P3 for mixed pins and SMD technology and the Neptune T for transparent material inspection.

AI-powered Development

As the inspection market and technology leader, Koh Young is using AI solutions to achieve its vision to expand process capabilities and factory performance. To realize this plan, Koh Young has created three more R&D centers to facilitate a quantum leap in technological leadership and competitiveness. Several of its latest offering use AI and machine learning solutions, these include the KY-P3, Neptune T, and KSMART software suite.

Automated Pin Inspection (API)

Built on its world-class True3D™ AOI technology, new enhancements to the KY-P3 help it breakthrough barriers associated with inspecting products combining tall pins and short SMD components. The enhanced KY-P3 lineup provides an automated back-end solution combining advanced high-resolution optics and innovative AI-powered vision algorithms for single, multiple, forked, and press-fit pins, as well as final optical inspection and shrouded connectors, while also inspecting traditional SMDs on the same product.

Typically, manufacturers required two separate machines for SMDs and pins, but the new KY-P3 Series with mixed technology capabilities, reduces machine investments by delivering a two-in-one solution for most applications. Because it uses a quantitative measurement-based approach, KY-P3 accuracy and repeatability is unsurpassed.

Joel Scutchfield, Sales Director for Koh Young America

Dispense Process Inspection (DPI)

The new Neptune T is the industry’s first 3D optical measurement solution for transparent material inspection. Using Koh Young LIFT technology (Laser Interferometry for Fluid Tomography), the Neptune T delivers non-destructive 3D inspection to precisely measure and inspect fluids – wet or dry. With its Machine Learning algorithms, the Neptune T accurately measures materials for coverage, thickness, and consistency with user-defined threshold settings. It also identifies bubbles, cracks, and other defects. Besides coatings, the Neptune T measures underfill, epoxy, bonding, adhesive, and more to deliver an exact measurement of transparent and translucent materials.

KSMART Process Control Software

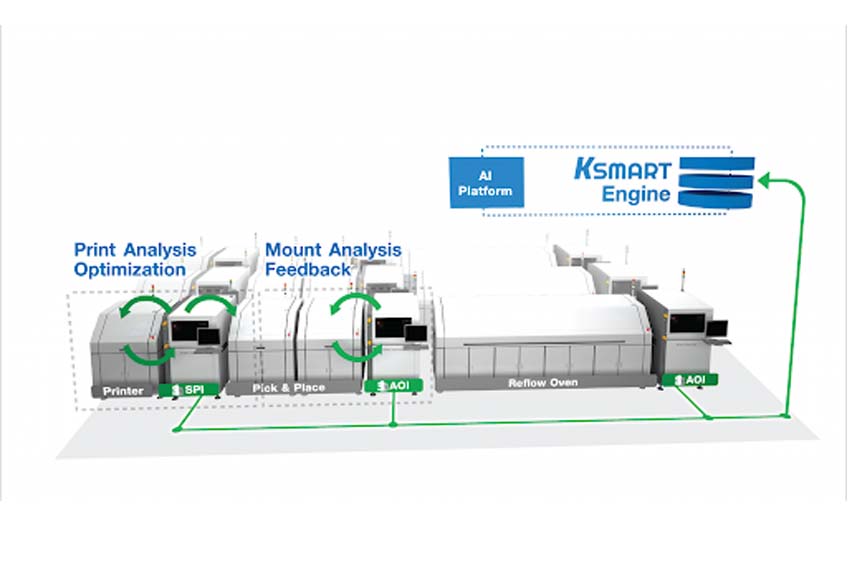

KSMART revolutionizes process optimization with set of complementary software modules. As a production process evolves, manufacturers can simply add modules as needed. KSMART collects data from across the factory for defect detection, real-time optimization, and traceability to improve metrics, increase quality, and lower costs. KSMART converts data into information, and then into knowledge for effective, quality-driven decisions. It delivers AI-powered process analysis and improvement tools that can deliver autonomous process optimization. In short, KSMART is the “Gateway to a Smart Factory.”

SMTA International Information & Registration

This year’s shift from an in-person conference to completely virtual event can be daunting for some attendees. SMTA is understands and has taken numerous steps to make attending and navigating the show simple and effective. For “how-to” videos and a navigation overview, just visit smta.org/mpage/smtai-virtual-experience. If you want more information, SMTA is hosting an interactive webinar to explain the process and answer your virtual event questions. The webinar is on 16 September 2020 from 1:30 PM to 2:45 PM EST, so register today on their website smta.org or directly at register.gotowebinar.com/register/2761719630419831055.

Above all, don’t forget to register for the event at smta.org/smtai. If you cannot attend the tradeshow, learn more about Koh Young and how its AI solutions are paving the way for applications beyond SMT at kohyoung.com